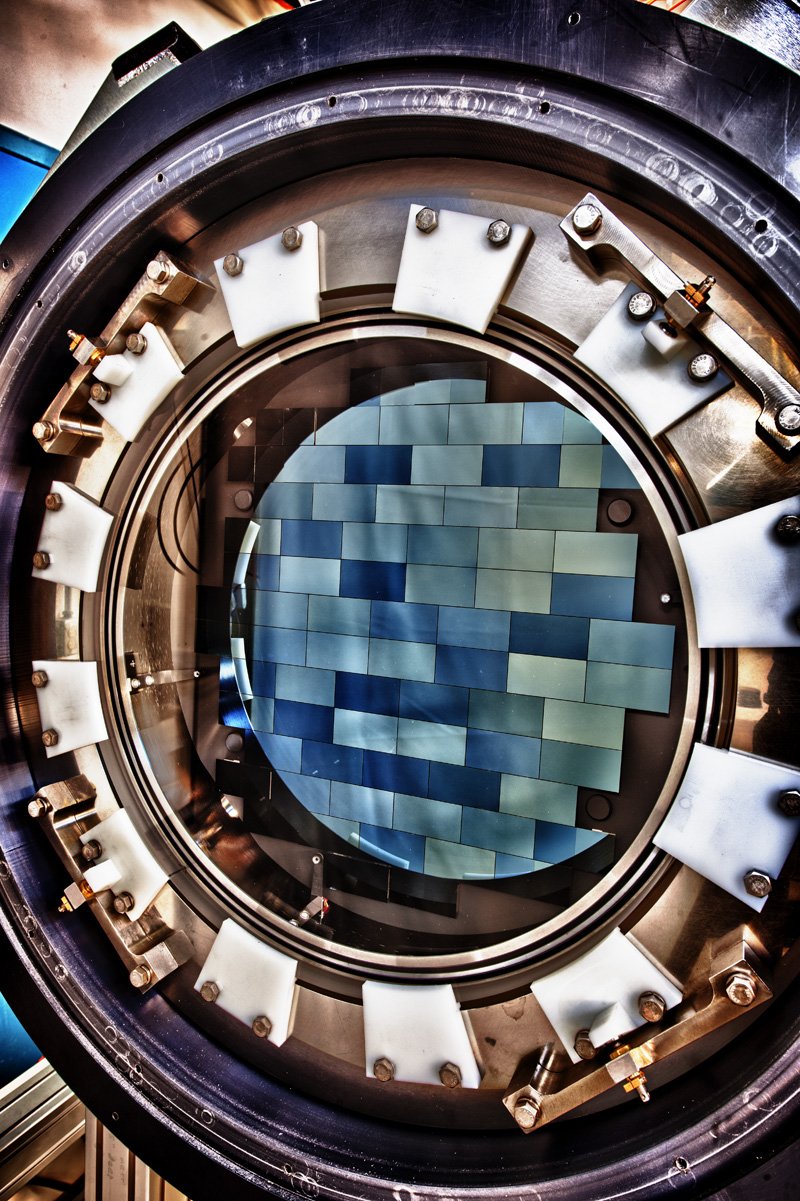

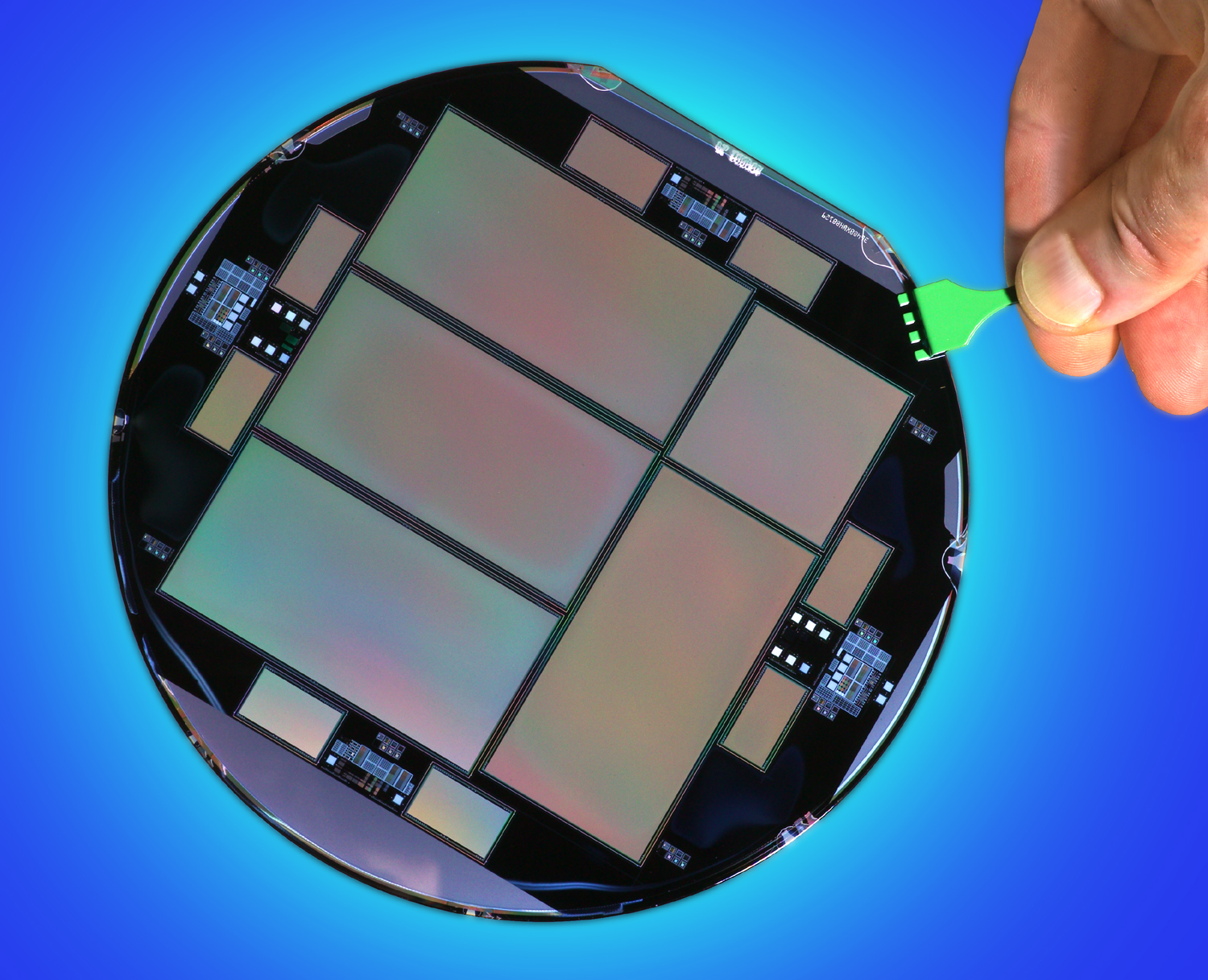

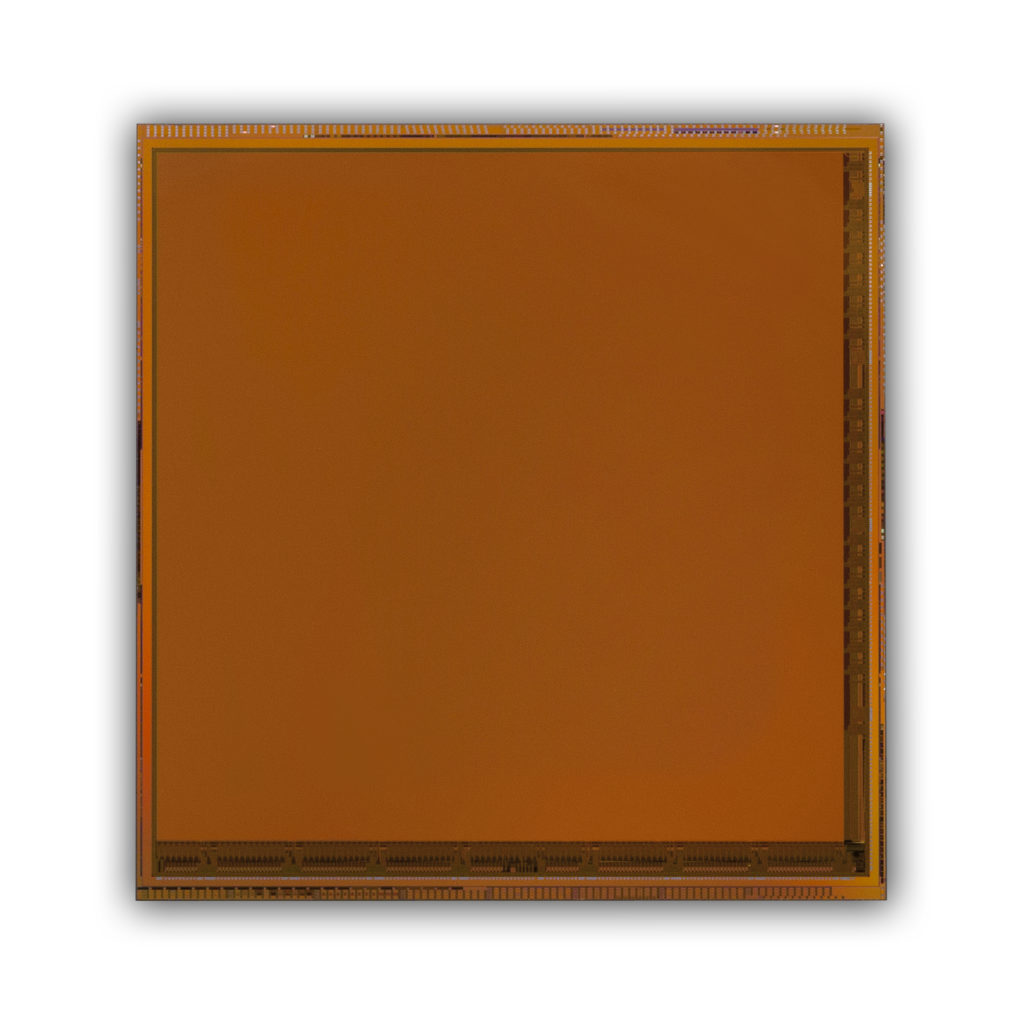

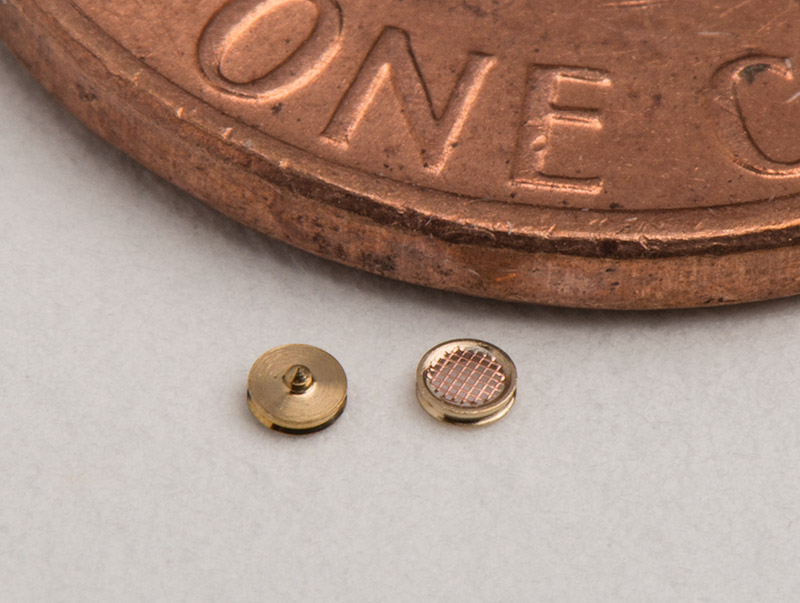

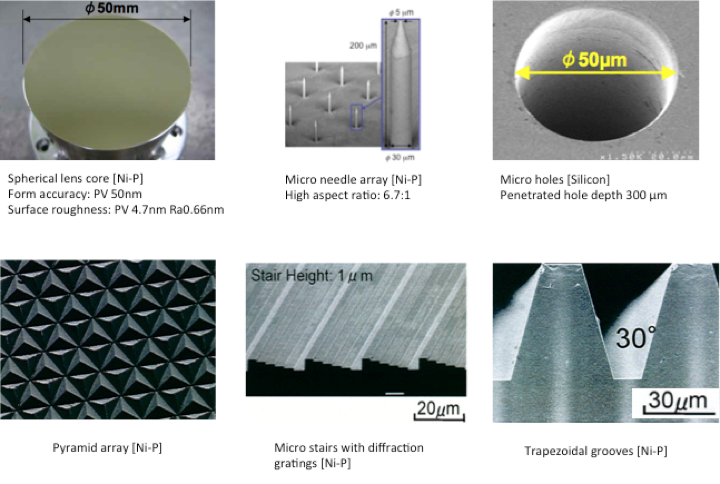

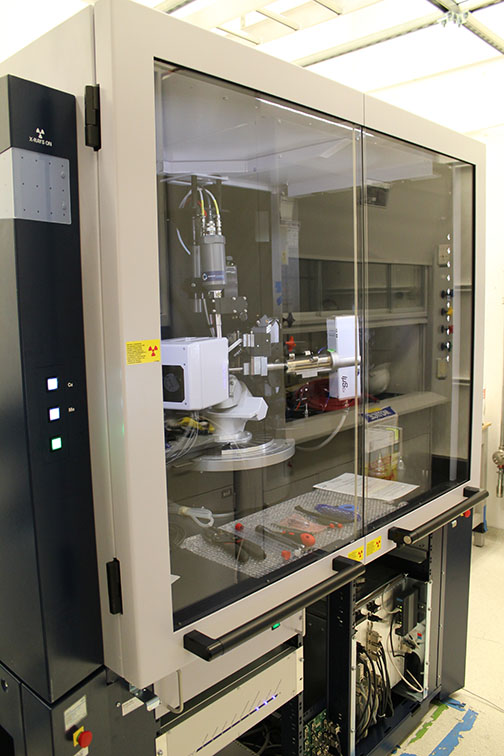

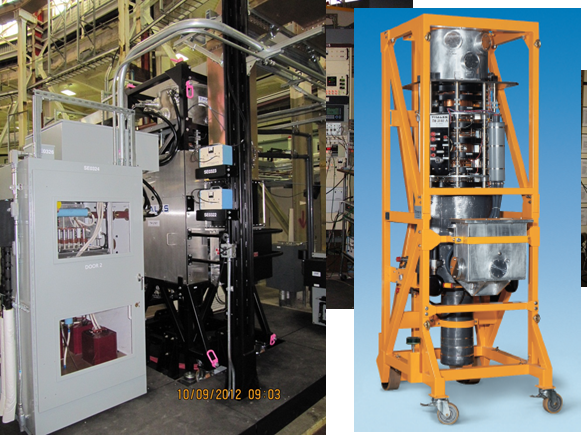

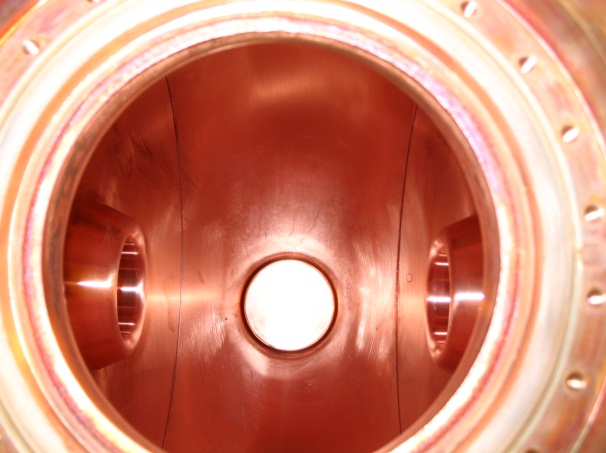

Imaging detectors such as charge-coupled devices (CCDs) are primarily used for astronomical observation and x-ray imaging. Our CCDs are noted for their exceptionally high, near-infrared sensitivity and capability to capture images billions of light years away. The Berkeley Lab MicroSystems Laboratory produces scientific CCDs for imaging and spectroscopic applications in astronomy as well as for the direct detection of x-rays at the Advanced Light Source.

Video: Making Sci-Fi a Reality (Electron Microscopy Imaging)