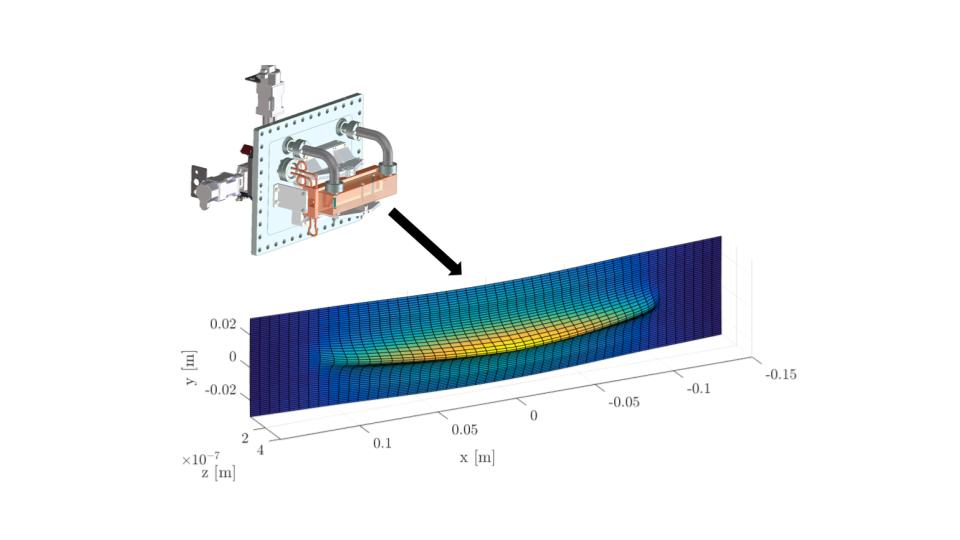

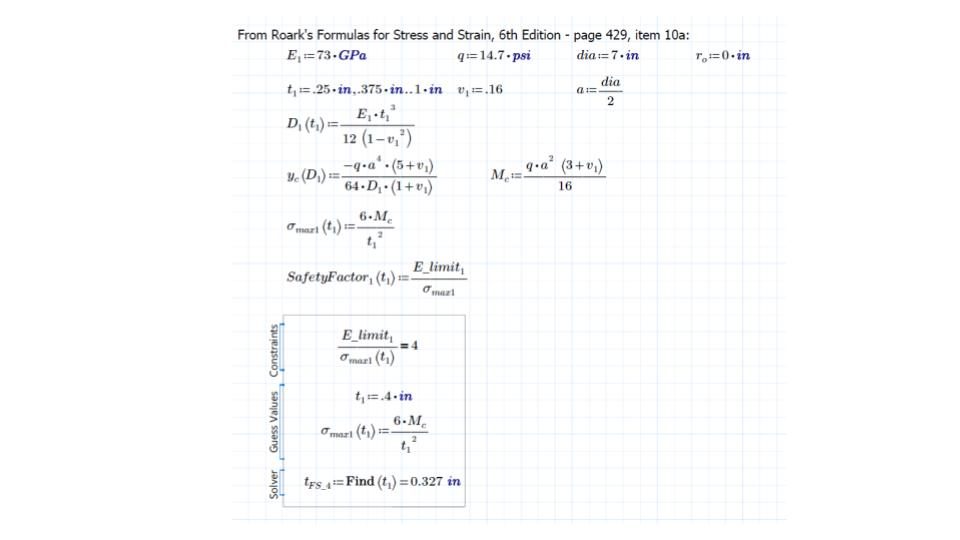

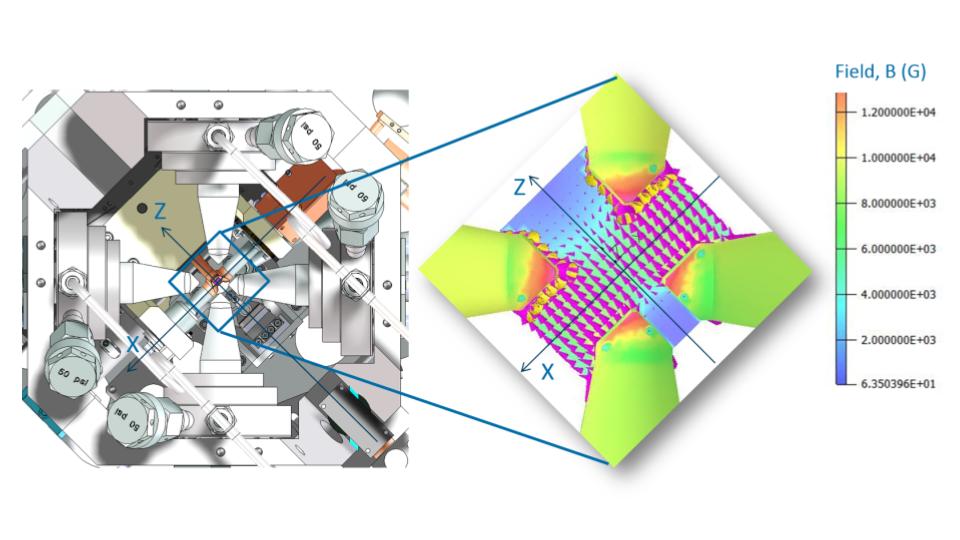

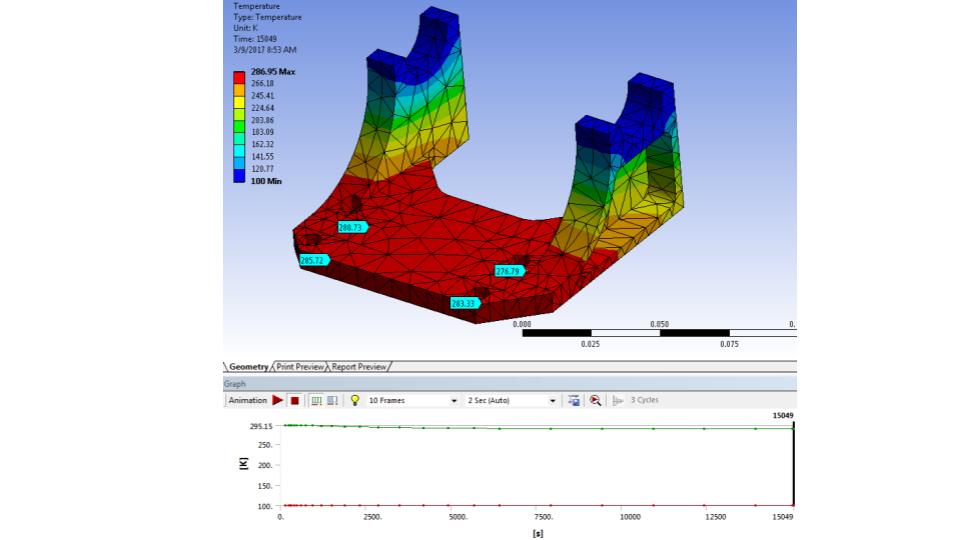

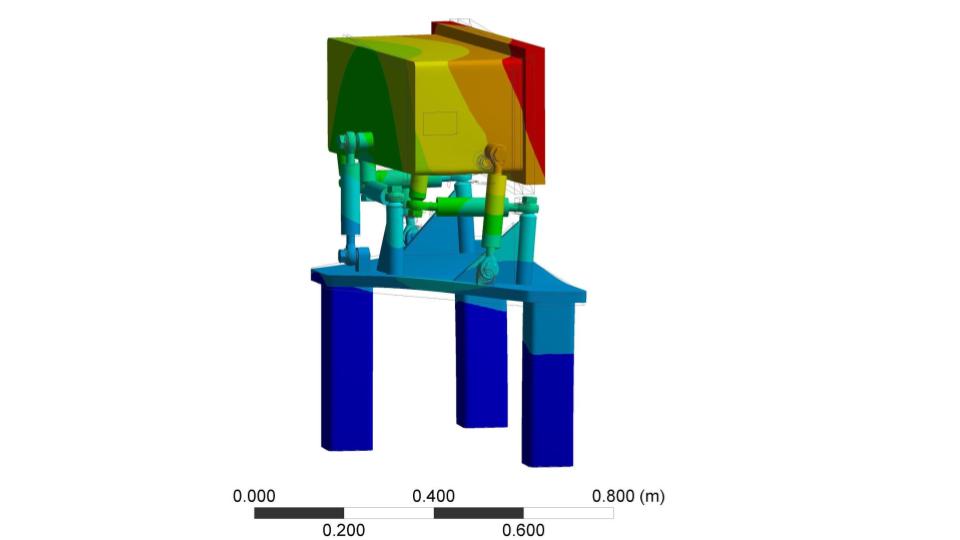

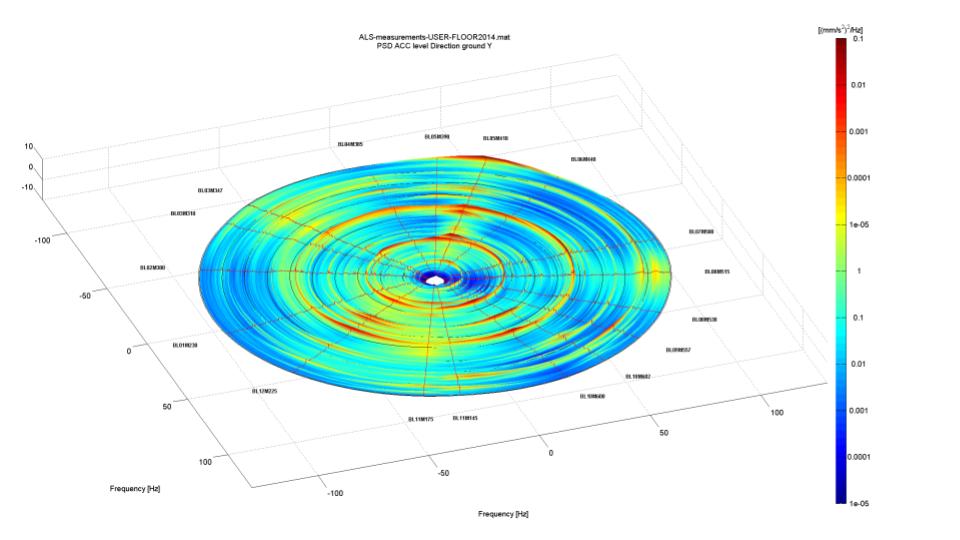

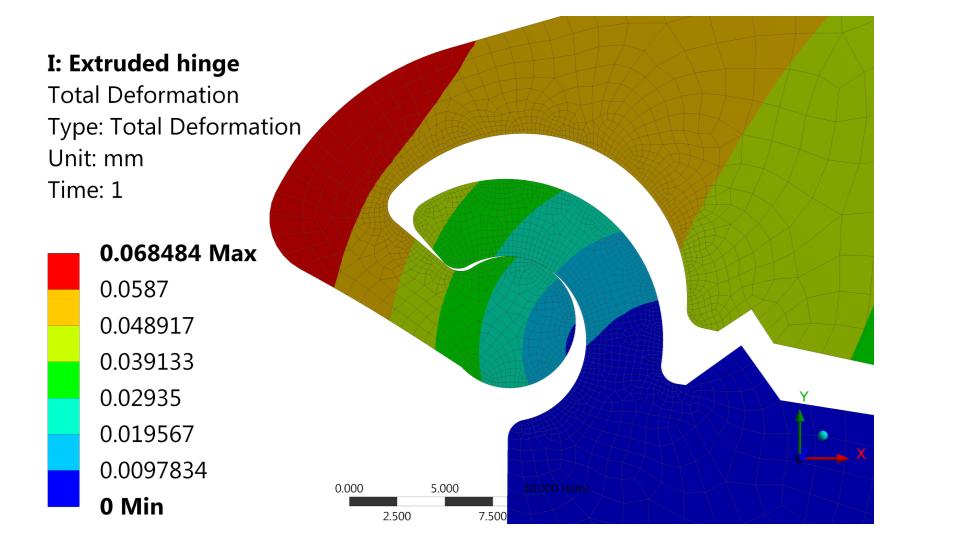

The Engineering Division provides world-class mathematical analyses of applications to help ensure the system functions as desired. Using a variety of analysis tools, including finite element analysis (FEA), we evaluate simple and complex designs for structural, thermal, vibration, fatigue, electromagnetic, and fluidic behaviors. The Engineering Analysis Team has both the tools and experience to apply appropriate analyses to support projects of varying size and complexity using a tailored approach to recommend the most effective path to solution.