- Location: Building 77

- The Weld Shop employs several different processes to join components together for large and small fabrication projects. The processes include stick welding (SMAW), tungsten torch welding (GTAW), wire feed welding (GMAW), oxy/acetylene, and carbon arc plasma cutting. Typical materials used include steel, stainless steel, and aluminum.

Weld Shop

Composites Shop

- The Composites Shop does research and development of composite materials, primarily for the optimization of structures with low mass and high stability. The shop has specialized expertise in the design and fabrication of Carbon Fiber Reinforced Plastics.

- Composites Capabilities

Microsystems Laboratory

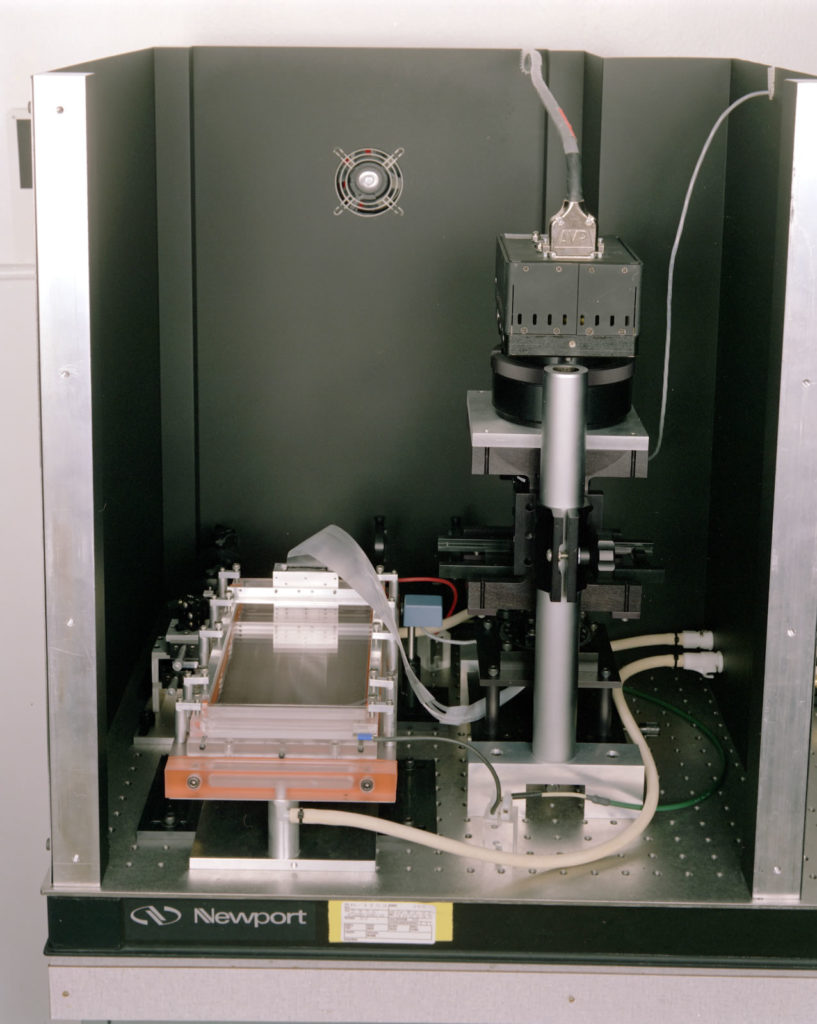

The Microsystems Laboratory (MSL) is a semiconductor processing facility specializing in the fabrication of various types of radiation detectors and integrated electronics on high resistivity silicon. The facility consists of 700 sq. ft. of Class 10 clean room space with environmental control of +/-1 F and +/- 2% relative humidity. Process capabilities include high temperature oxidation, deposition of thin films, and diffusion of impurity dopants, dry plasma etching, wet chemical etching and cleaning operations, and photolithography.

Semiconductor Detector Laboratory

![]() The Berkeley Lab’s Engineering Division Semiconductor Detector Laboratory provides the infrastructure and expertise for the development and production of semiconductor-based radiation detectors and detection systems. The facility consists of a class 100 clean room, class 10,000 processing and testing area, and a mechanical processing area. We use mechanical and wet chemical processing, thin film deposition, photolithography, wire bonding, and detector characterization to process Ge, CdZnTe, and SI. Several configurations are used including, diffused, implanted, surface barrier, and amorphous contacts, including strip, orthogonal strip, and point contact.

The Berkeley Lab’s Engineering Division Semiconductor Detector Laboratory provides the infrastructure and expertise for the development and production of semiconductor-based radiation detectors and detection systems. The facility consists of a class 100 clean room, class 10,000 processing and testing area, and a mechanical processing area. We use mechanical and wet chemical processing, thin film deposition, photolithography, wire bonding, and detector characterization to process Ge, CdZnTe, and SI. Several configurations are used including, diffused, implanted, surface barrier, and amorphous contacts, including strip, orthogonal strip, and point contact.

Sheet Metal Shop

- Location: Building 77

- The Sheet Metal Shop offers precision cutting, forming, and joining of a variety of thin materials including, steel, stainless steel, copper, brass, aluminum, tantalum, and titanium. The shop is equipped with various tools including a metal spinning lathe and glove-box welding system for producing complex shapes and delicate welds in a clean atmosphere.

Researcher Shop

- Location: Building 77

- Available to: Interested researchers/interns/postdocs and others who have reviewed the Researcher Shop General Policy and Researchers Shop Safety Policy, and have been qualified and authorized by designated Central Fabrication personnel.

- Our researcher shop is available for qualified, authorized researchers and students to complete relatively simple machining projects. The shop is equipped with a Bridgeport milling machine, engine lathe, tool room lathe, drill press, and other tools. An experienced machinist oversees the researcher shop, offering setup and/or machining advice or direction if needed.

Technician’s Machine Shop

- Location: Building 77

- Our technician’s machine shop, offers several lathes, milling machines, drill presses and ancillary equipment for the convenience of the Division’s qualified mechanical technicians.

Machine Shop

- Location: Building 77

- Behind the Scenes Video

- Our fabrication machine shop, often referred to as “the shops,” produces components or features ranging from several microns to several meters in size using a broad range of fabrication technologies. We offer directly applicable experience, accessible staff, and a broad range of services.

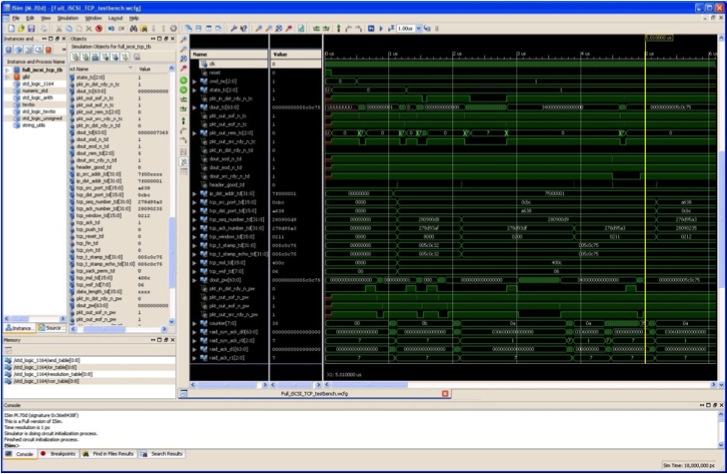

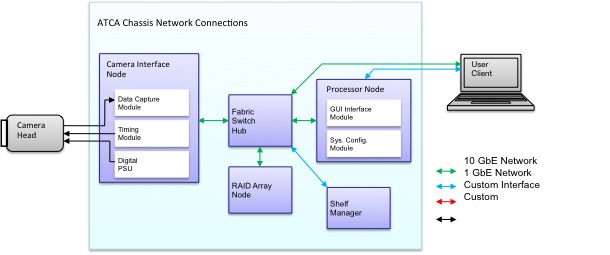

Data Acquisition and Control System Software

Many Engineering projects involve collecting scientific data and software is often used to facilitate this process. Specialized software is developed to meet requirements of the various sensors and data rates of the experiments and to process and store the data. In many projects, the need for Engineering Software goes beyond collecting data and includes controlling hardware such as power supplies, motors, heating and cooling equipment to support the experiment or facility. These software systems are often a collaborative effort with our scientific partners, but those components that interact directly with the low level sensor hardware are most often designed, constructed, and supported by Engineering Division software engineers. This software has tight integration with the low level hardware and often has difficult timing, processing and performance requirements that must be met for a successful experiment.

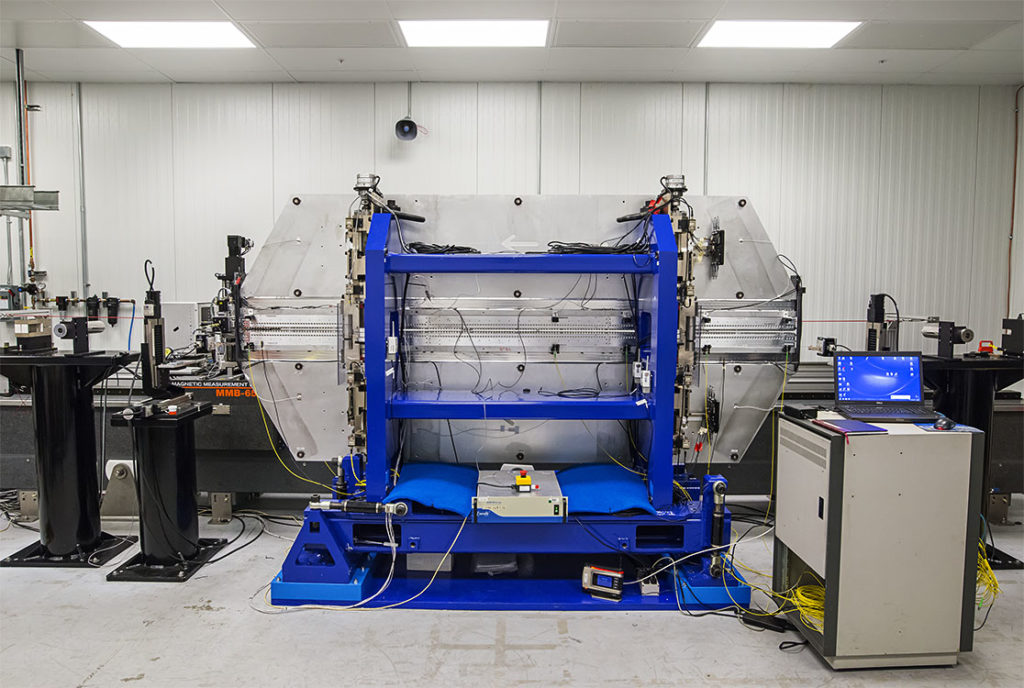

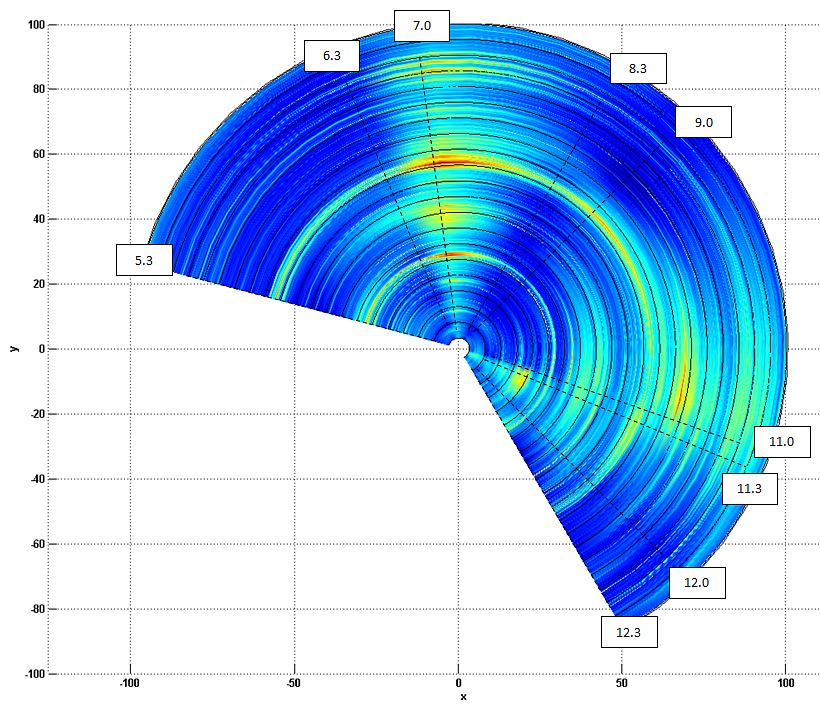

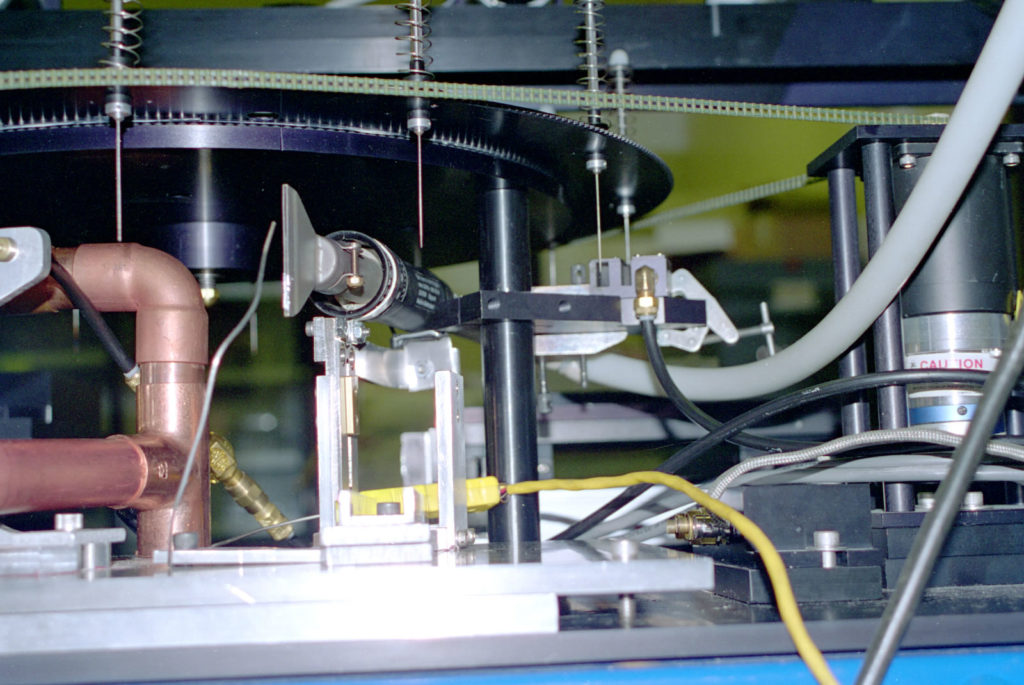

Magnetic Measurements

Magnetic Measurements characterize magnetic fields produced by magnetic devices such as dipoles, quadrupoles, combined function magnets, and undulators. At the Berkeley Lab, most of the devices measured are installed in a particle accelerator. The particle beam trajectory and properties depend strongly on the magnetic field. Different measurement techniques are used: Hall probe mapping, rotating coils, wire techniques (stretched wire, pulsed wire, rotating wire) to achieve the desired results. Each of these methods allows us to determine the quality of the magnetic field produced and ultimately the quality of the particle beam itself.

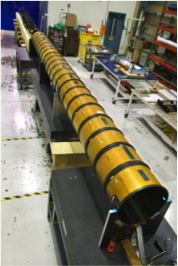

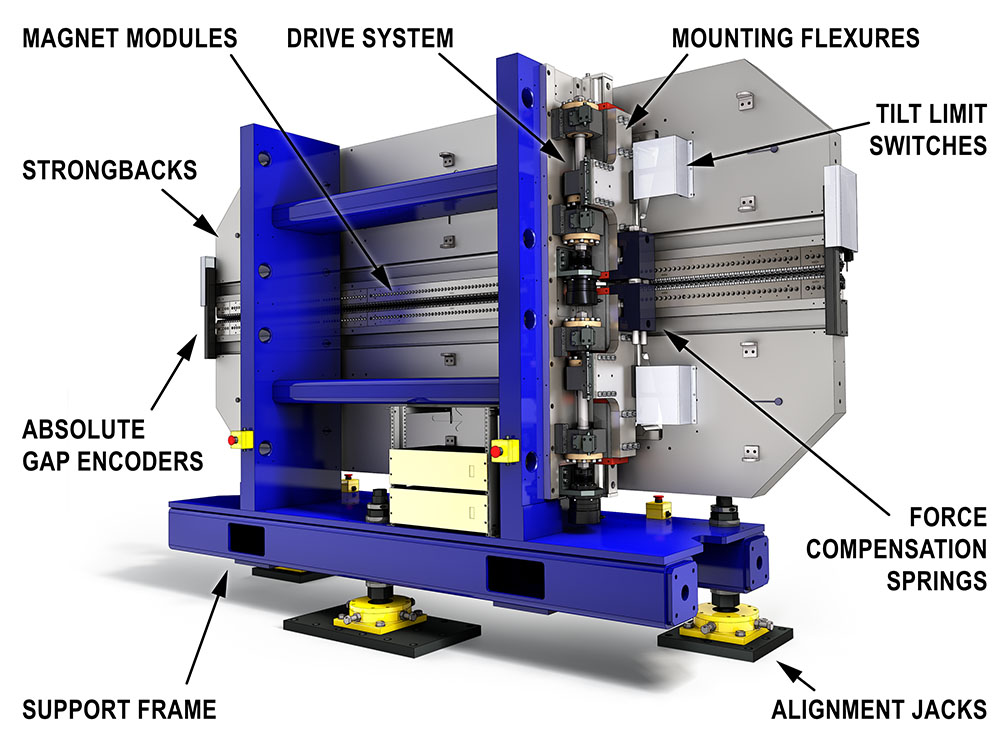

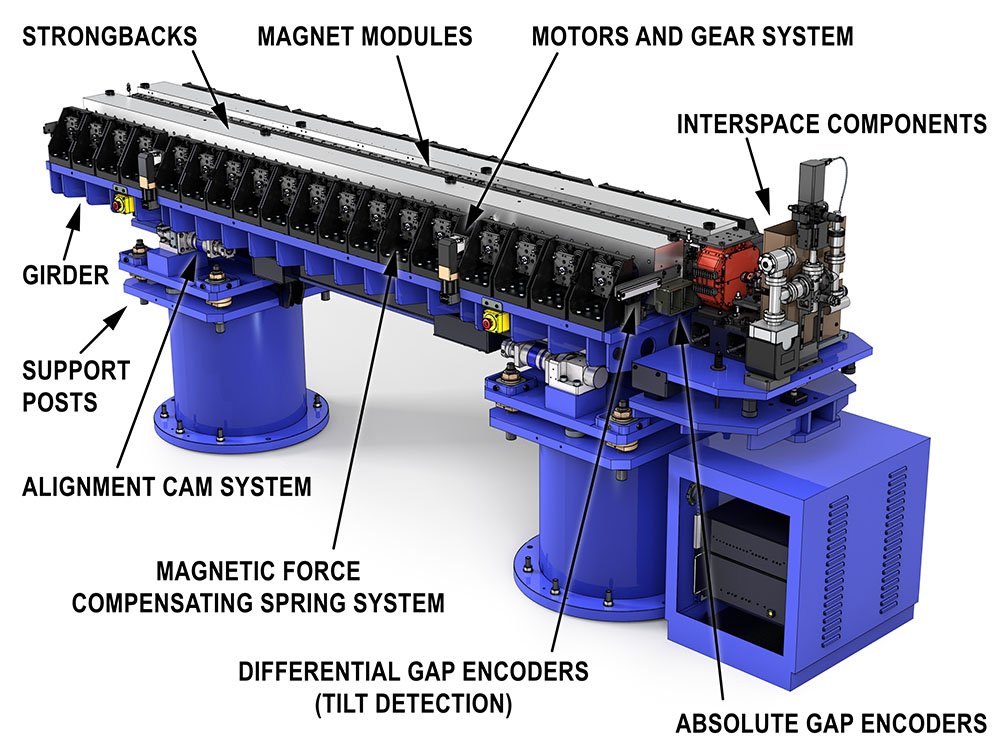

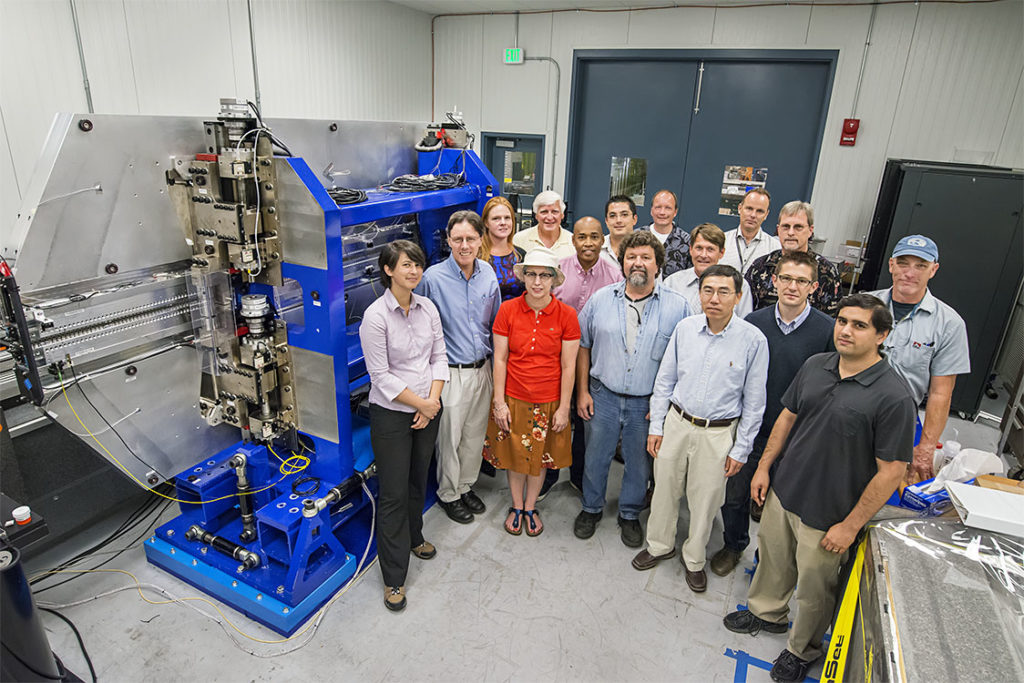

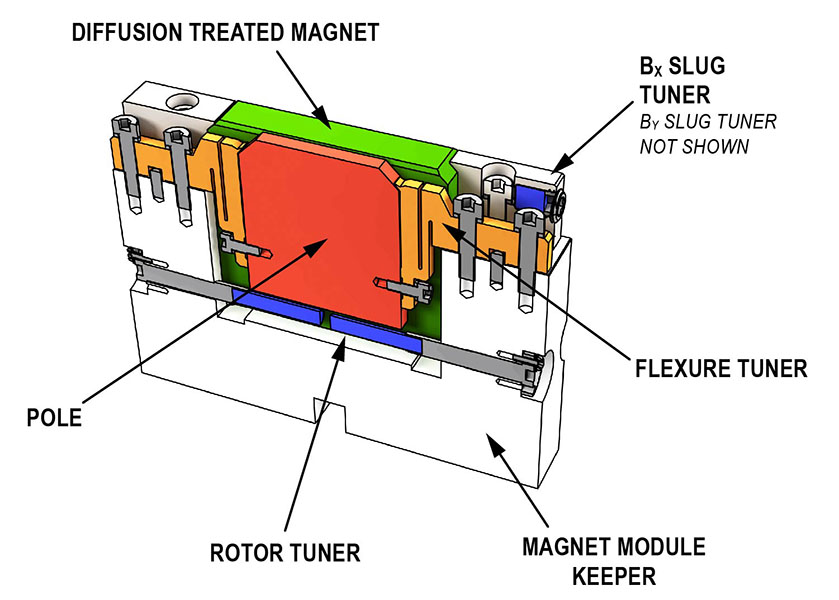

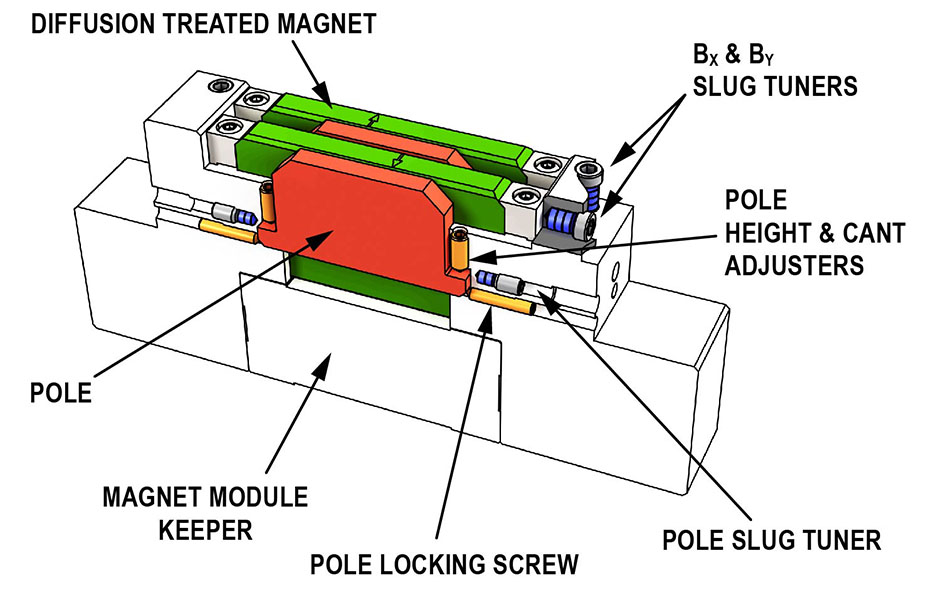

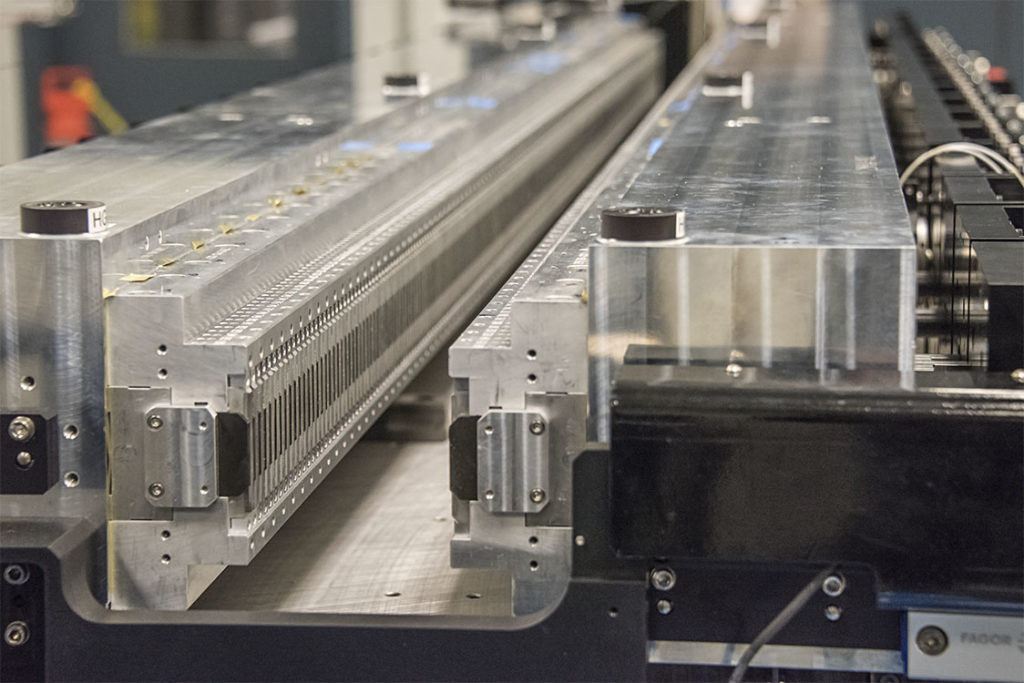

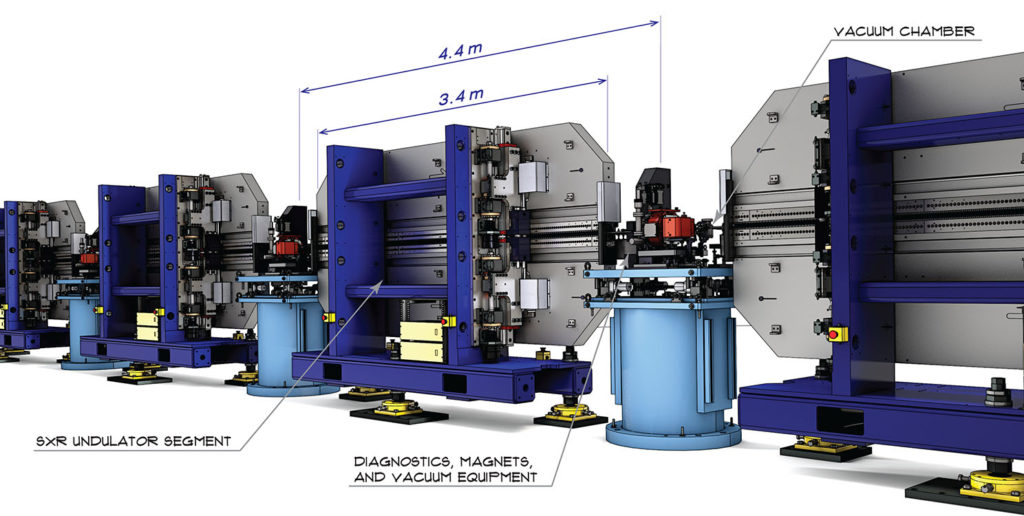

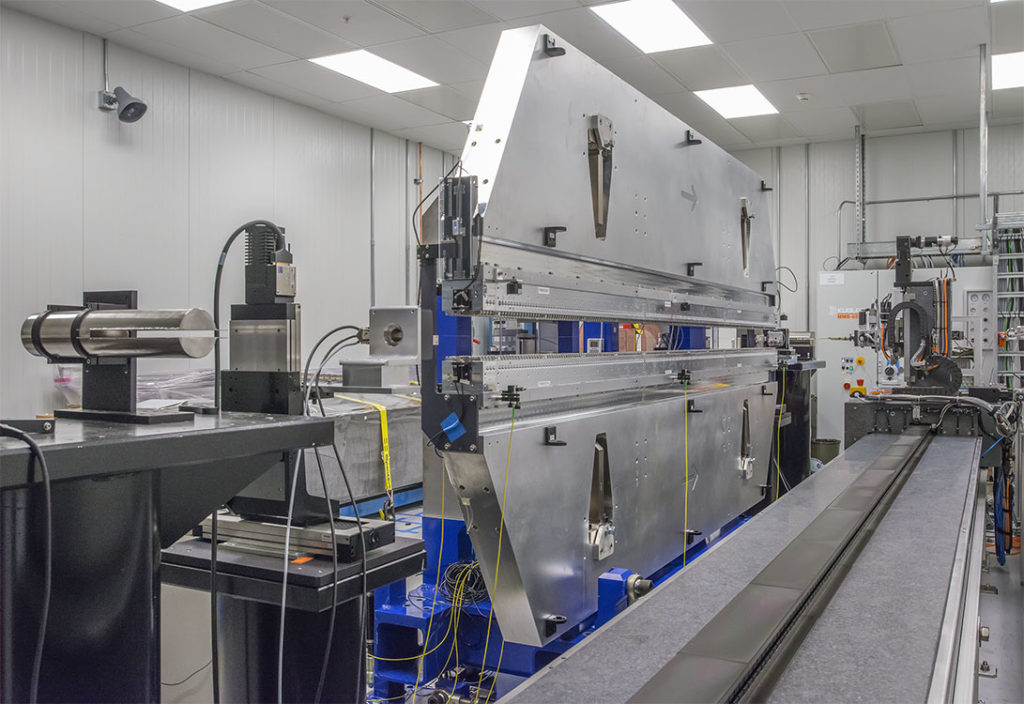

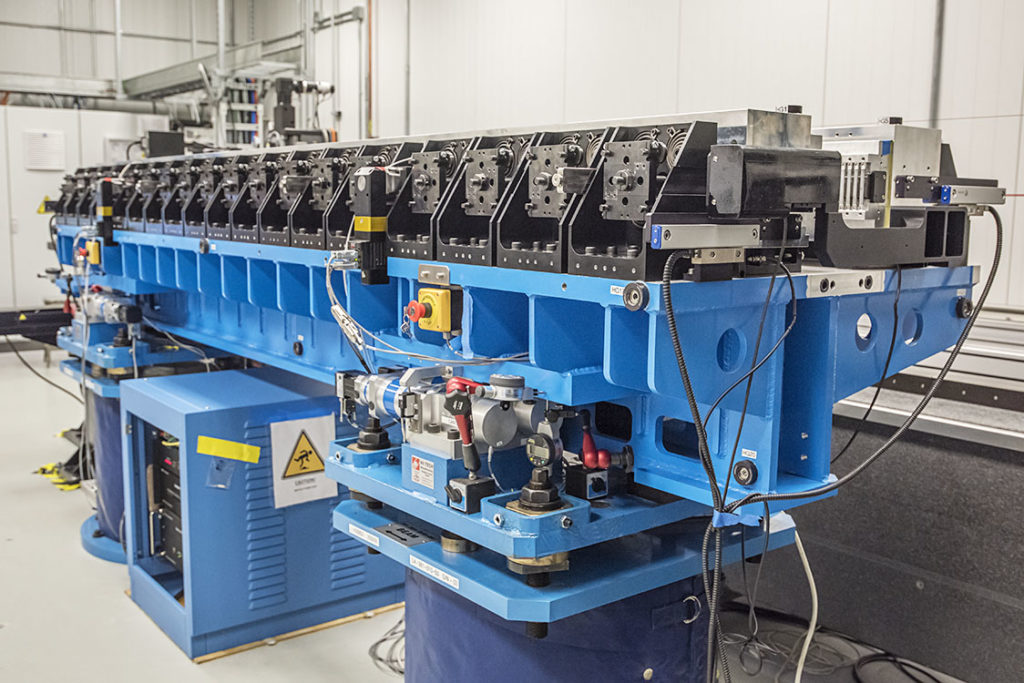

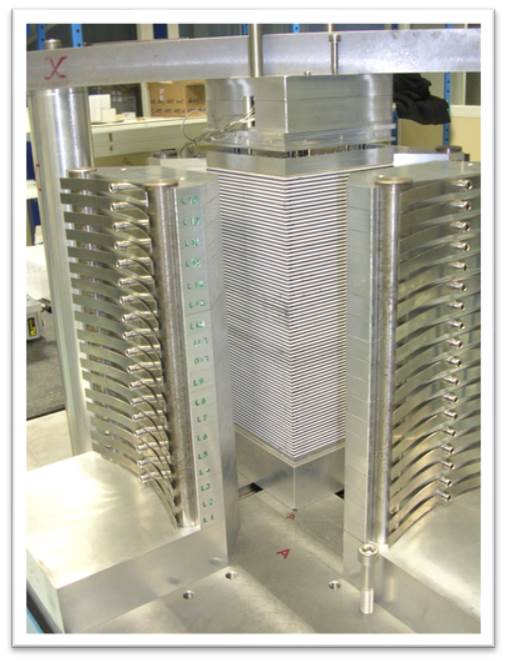

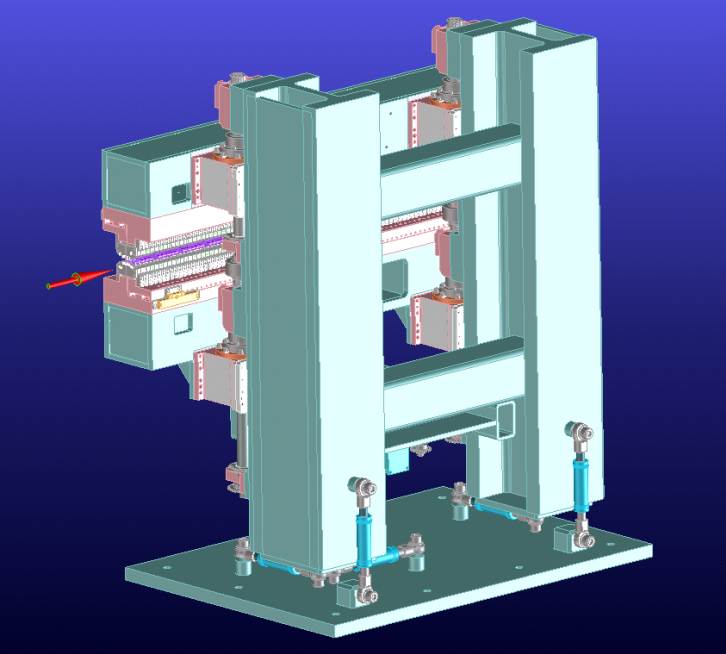

Undulators

An undulator is a periodic magnetic structure that serves as a critical component in synchrotron light sources and free electron lasers. Light, typically in the extreme ultraviolet to x-ray wavelengths, is produced when an electron beam passes through the periodic field. The wavelength is tunable by varying the magnetic field strength or the electron energy. Berkeley Lab’s Engineering Division has been at the forefront of undulator development since Klaus Halbach’s development of permanent magnet and hybrid (permanent magnet with high permeability poles) undulator structures, which was a key to the development of third and fourth generation light sources. In recent years, we have also been a leader in the development of NbSn3 superconducting undulators. The division designs and fabricates state-of-the art undulators for the Advanced Light Source. As one of the biggest construction projects we built approximately 60 undulators for LCLS-II, the world’s most powerful free electron laser at Stanford Linear Accelerator Center (SLAC).

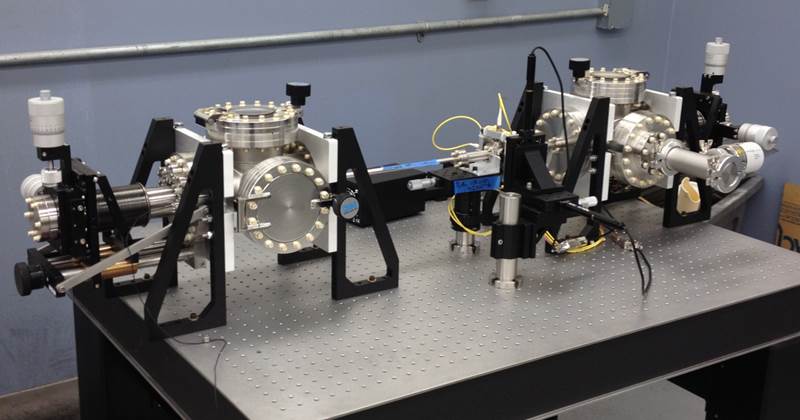

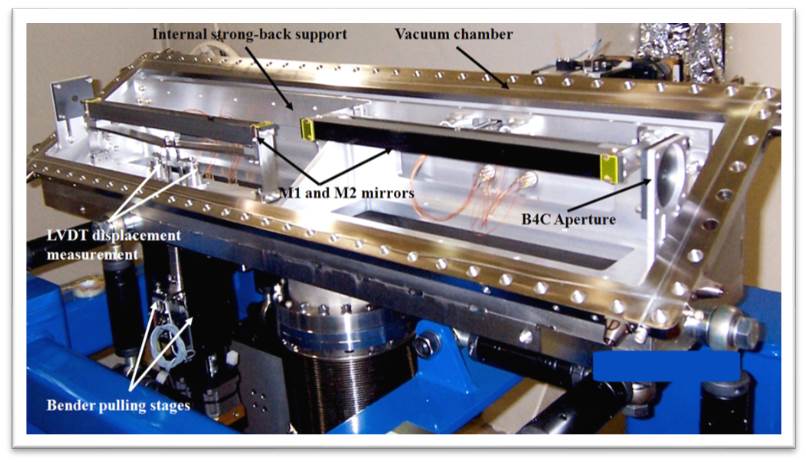

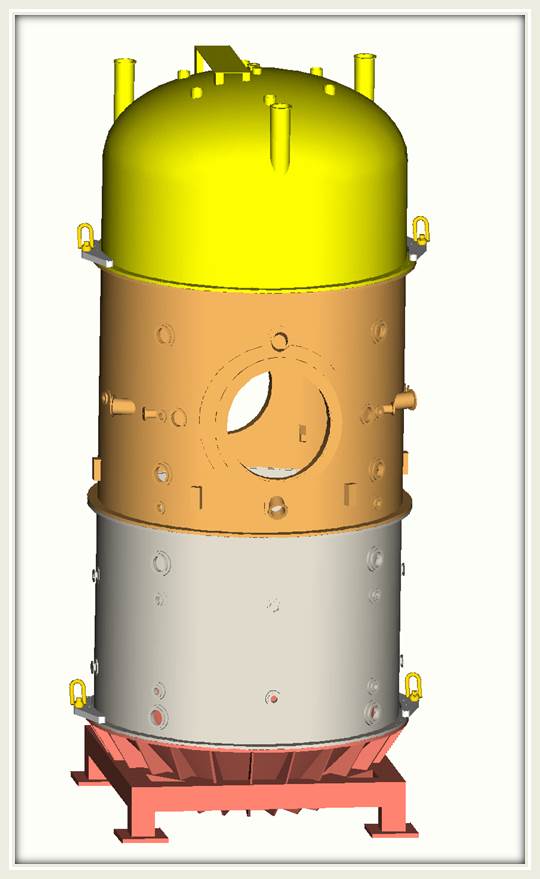

Ultra-High Vacuum Systems

Vacuum chambers are used to produce low-pressure environments for a multitude of experimental needs. We design and fabricate one of a kind vacuum chambers and components for operation in ultra-high (UHV) and extreme ulta-high vacuum (XHV) regimes. Our fabrication and assembly shops test materials and components for UHV compatibility and specialize the the fabrication, handling, cleaning, and processing of the components.

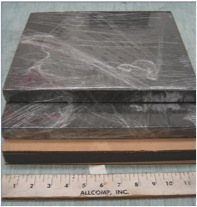

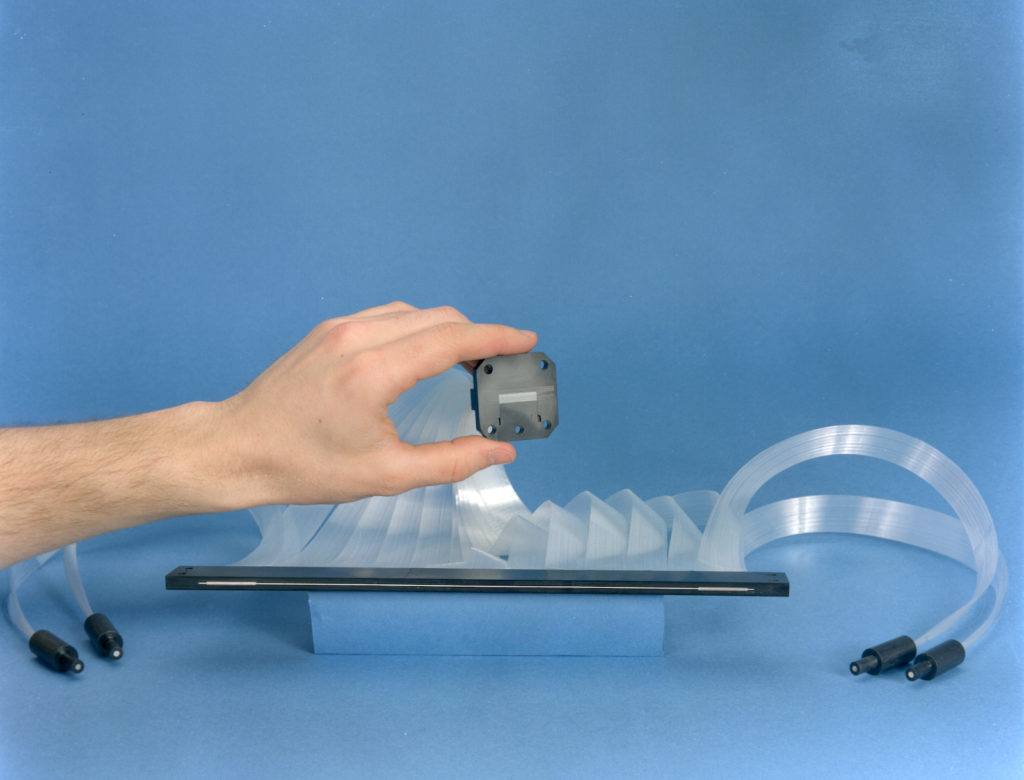

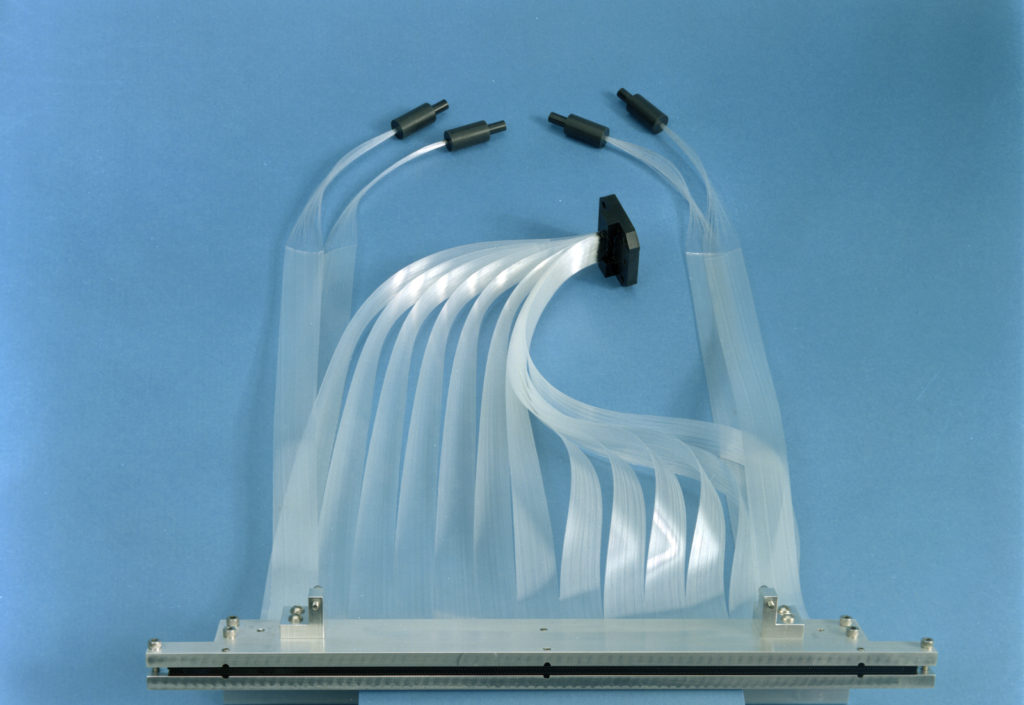

Composites

A composite is a combination of two or more materials that yield a new material with desired properties (i.e., non-magnetic/magnetic or non-conductive/conductive). Our specialization is in design and fabrication of high performance Carbon Fiber structures and precision bonded assemblies (incorporating both metallic and composite components) for Silicon Tracking Detectors. Using carbon fiber composites, we design very low mass, ultra-stable support structures for Silicon Tracking Detectors used in High Energy and Nuclear physics experiments. Our designs often integrate cooling, data, and power into the support modules. In addition to Silicon Tracking Detector Structures, we use carbon or other fiber composites to develop supports for other structures, including apparatuses at the Advanced Light Source (ALS). The Berkeley Lab Engineering has developed techniques and tooling to design and fabricate these structures with precision.

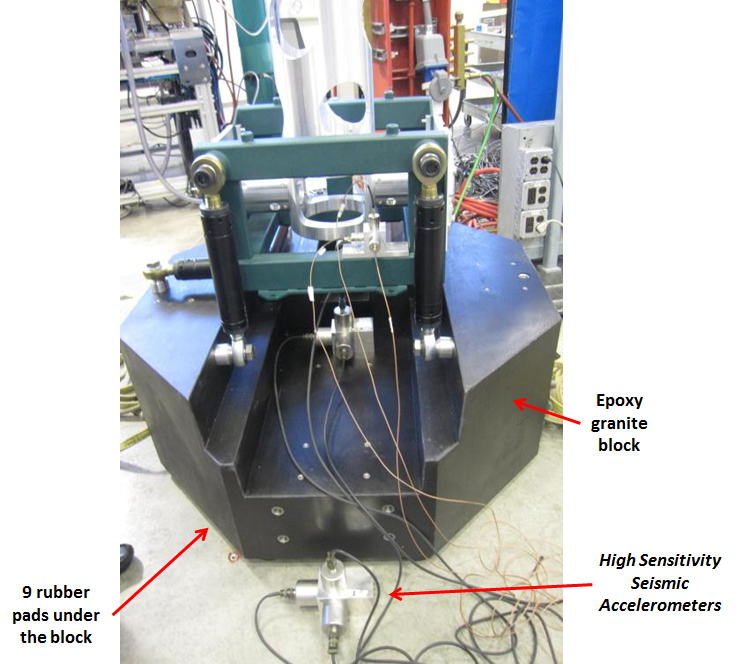

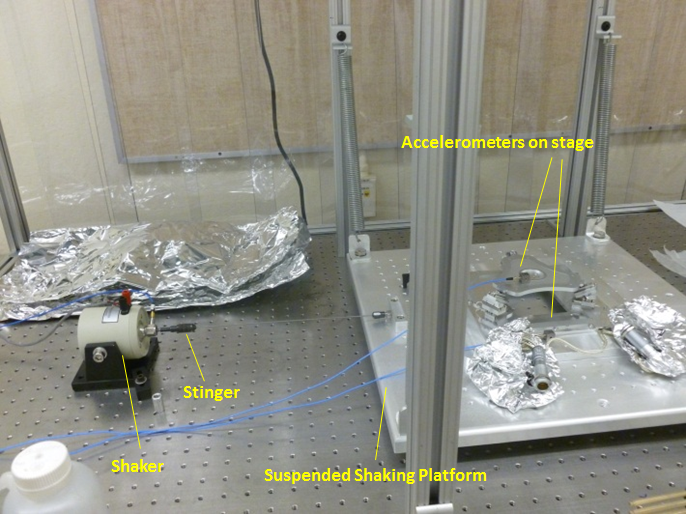

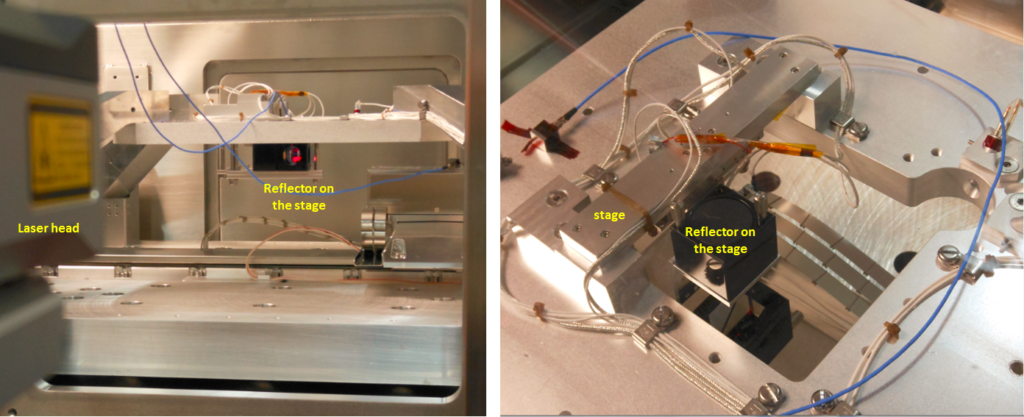

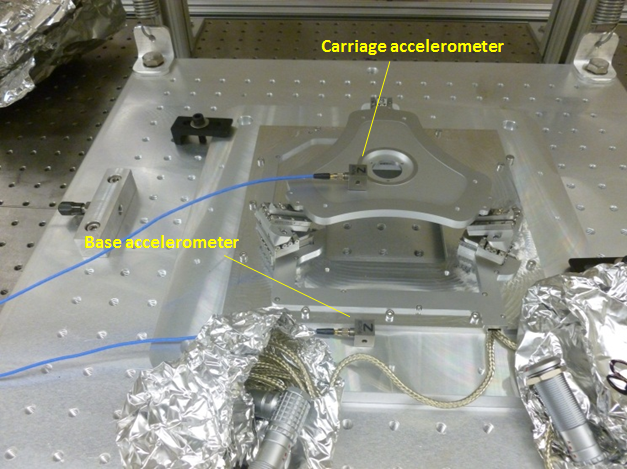

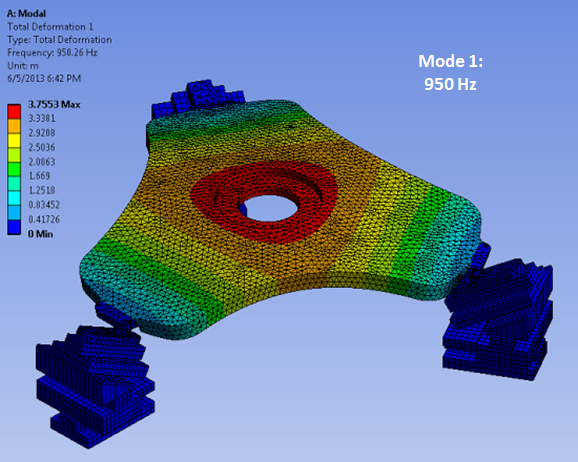

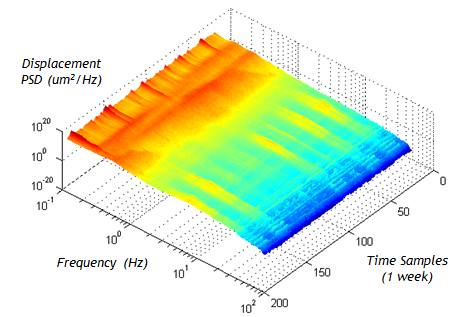

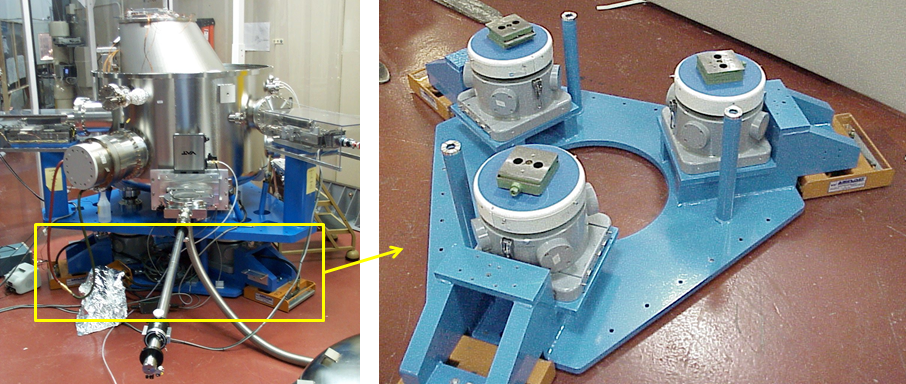

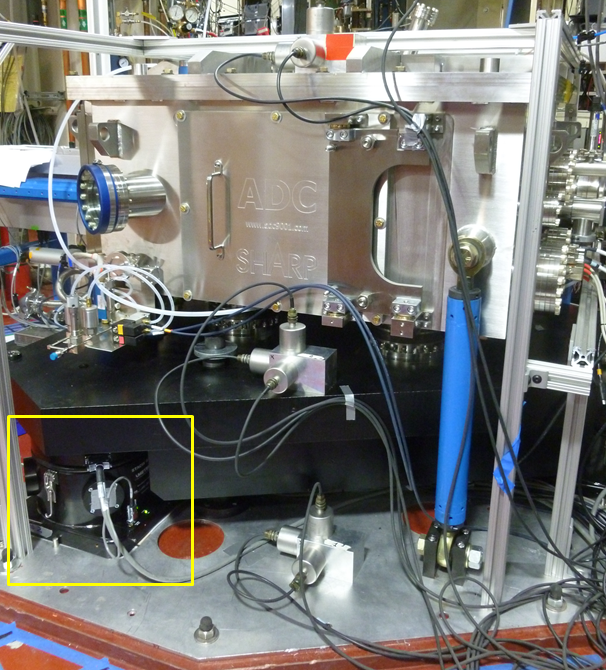

Vibration Analysis & Control

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The oscillations may be periodic or random but most often, vibration is undesirable. To mitigate the impact of vibration, we can either decrease the intensity of the vibration source or decrease the sensitivity of the equipment. Vibration sources and equipment sensitivity can be characterized using measurements from seismometers, accelerometers, or interferometers. We analyze the measurements to determine what structural improvement, vibration damping and/or isolation strategy can be implemented to mitigate the impact of vibration. Environment vibration measurements, careful design, and predictive modeling using modal analysis or harmonic response can be used to evaluate performance.

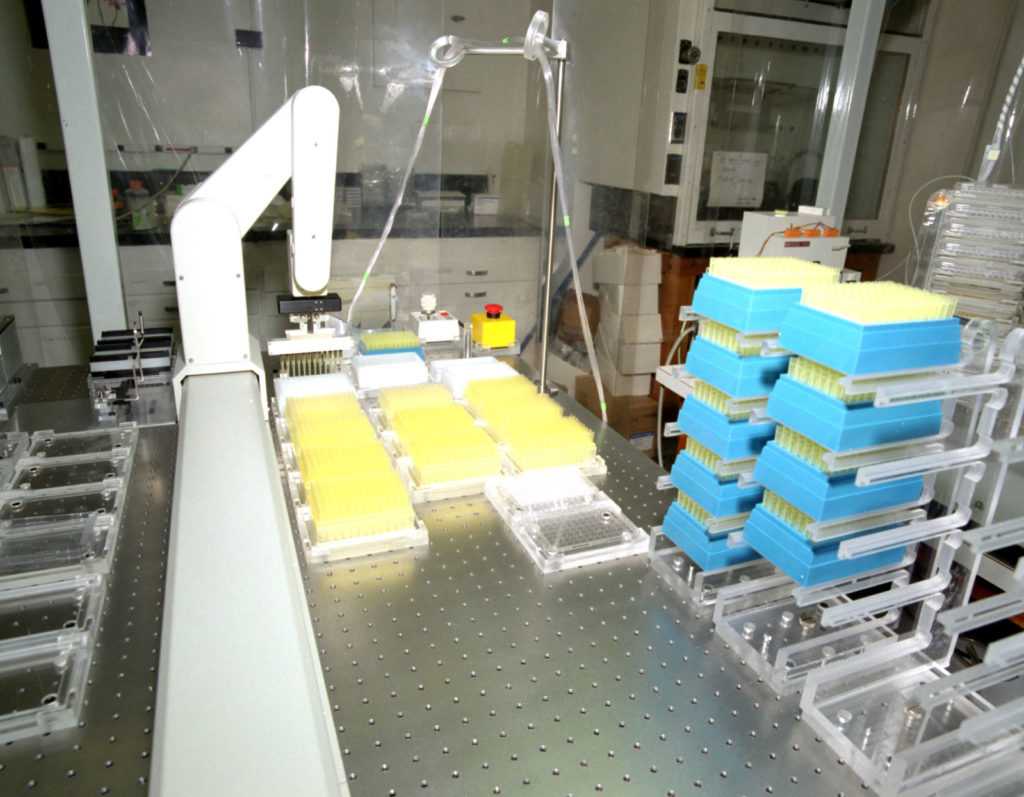

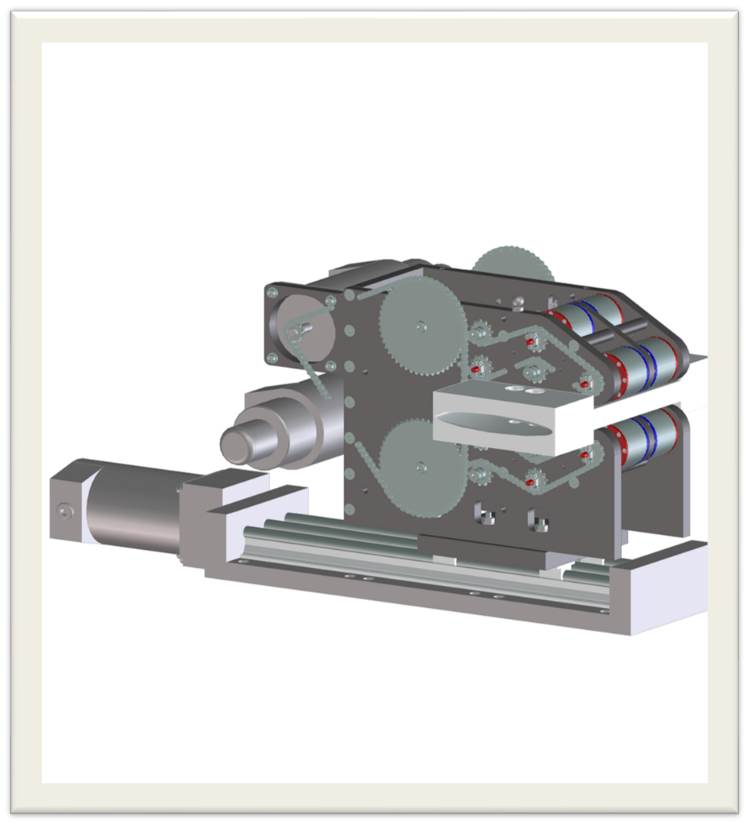

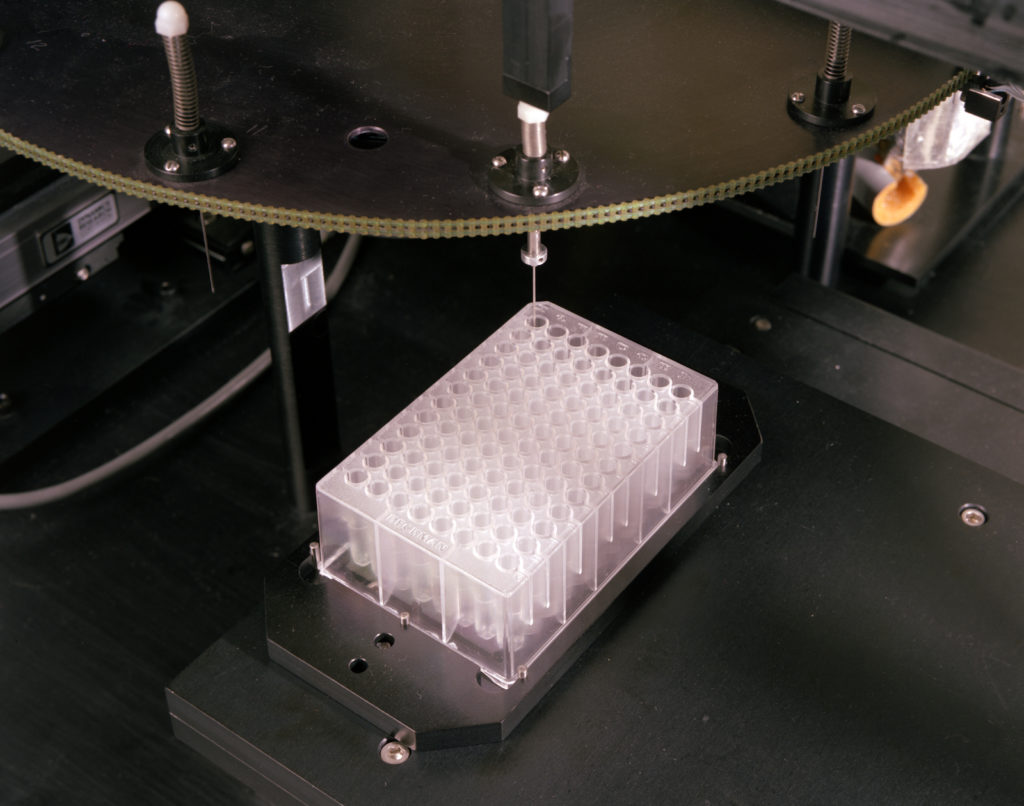

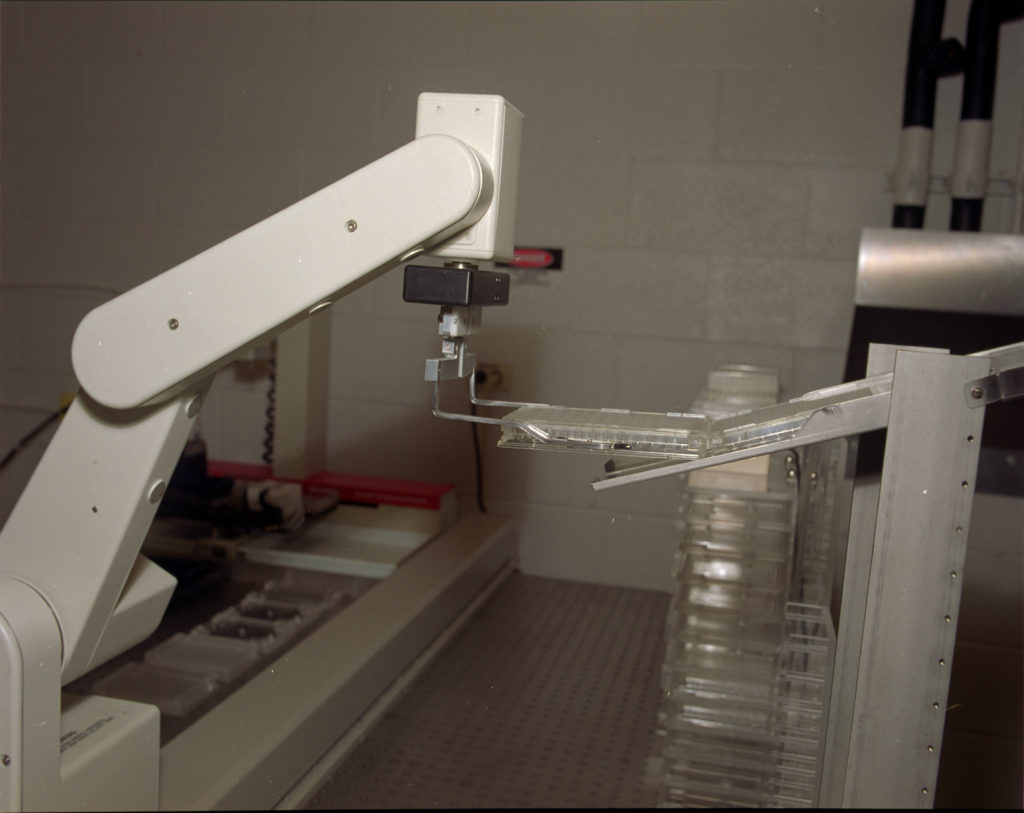

Robotic Systems & Motion Control

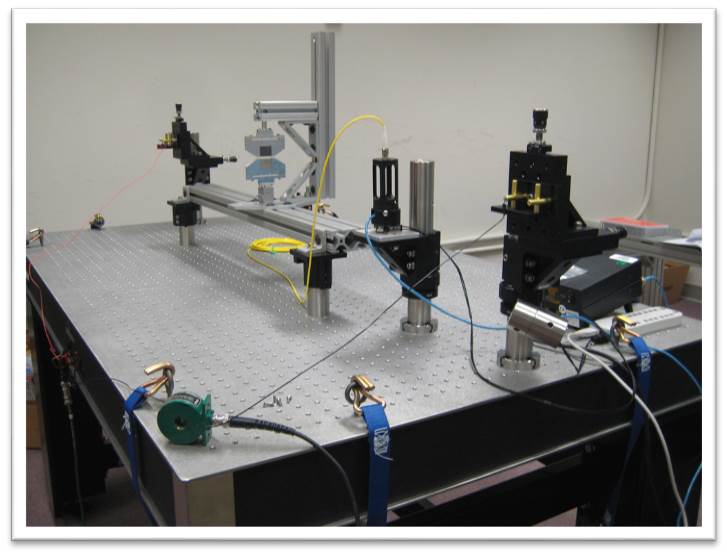

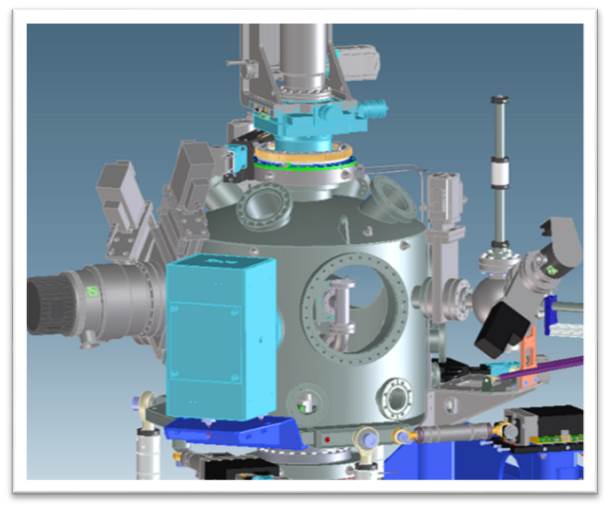

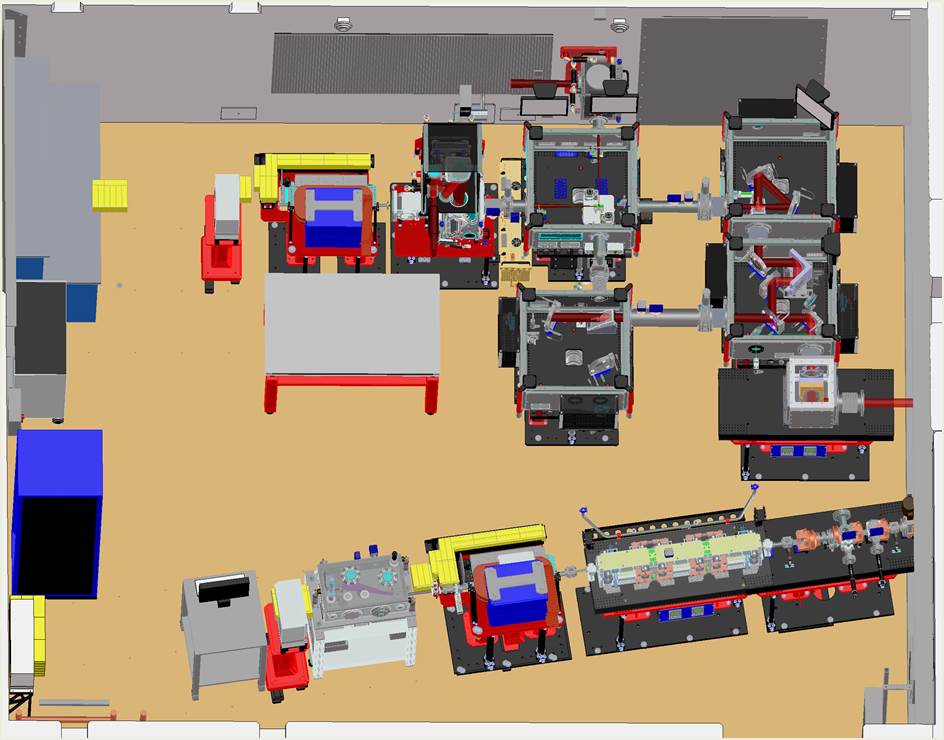

In industry, motion control and robotics is typically used to automate the movement, transport, or assembly of components or products in the manufacturing process. At the Berkeley Lab, motion control and robotics are used to automate scientific tools, improving the speed and quality of data acquisition. Our motion control applications include laser and X-ray optics alignment, sample positioning, precision control of magnet assemblies and speed control for audio reconstruction. Robots are used in special applications and particularly in highly repetitive task in genomics that can be replaced by a pick-and-place robot, or a task in an exclusion area such as placing a protein crystallography sample on a manipulator to perform X-ray diffraction. For both these tasks throughput is increased and error reduced by eliminating human operators.

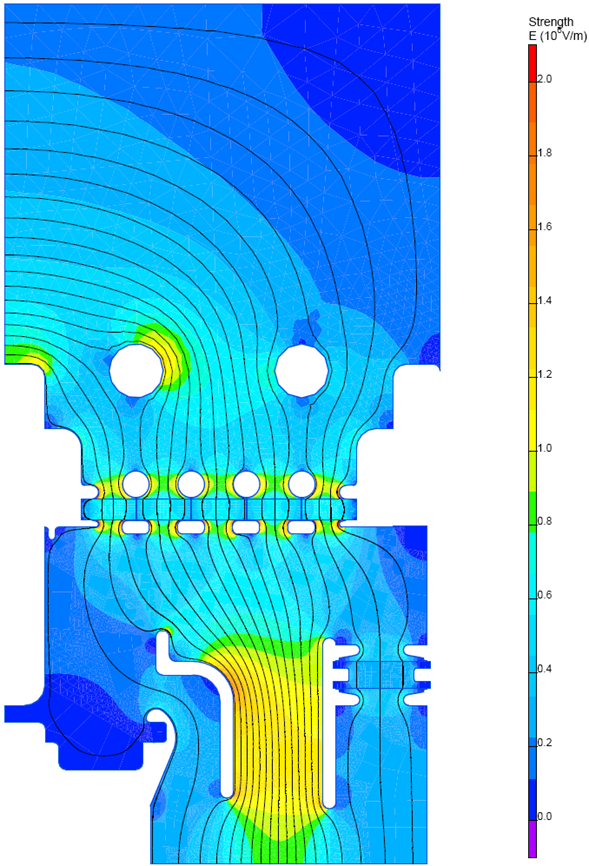

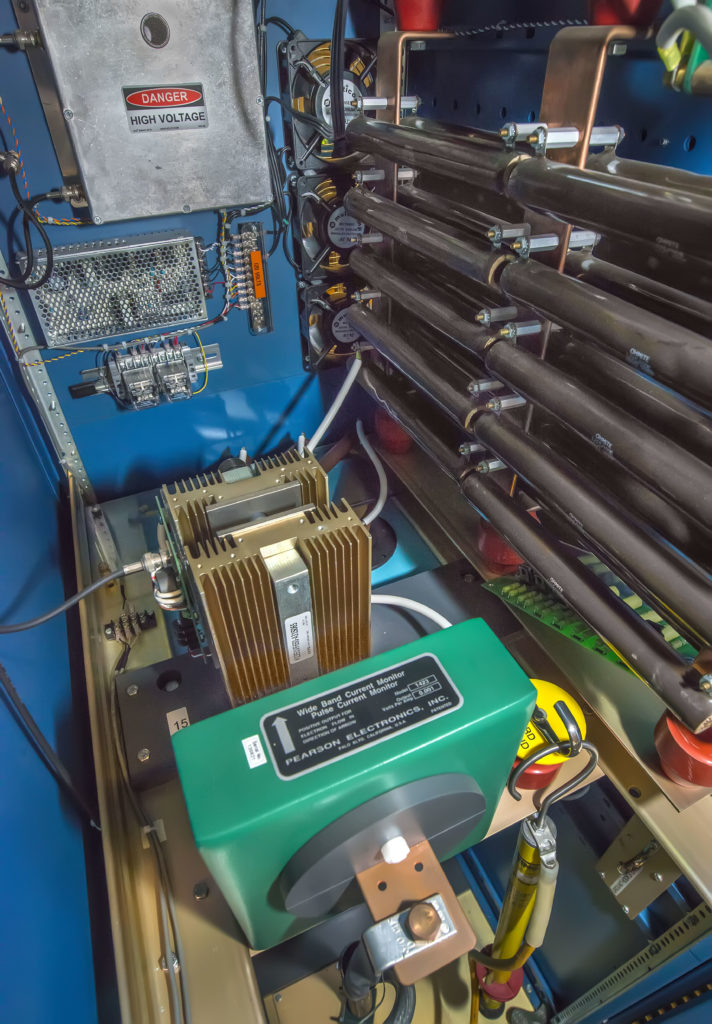

Pulsed Power and High Voltage

Pulsed power is a field of research which explores methods of providing high peak power (the product of the voltage and the current) to a load in the form of short pulses (nanoseconds to microseconds duration). These systems typically include a primary power supply, energy storage capacitor, and a switch which transfers the pulse of energy to the load. Loads may be electromagnets, induction accelerator cells, electrostatic accelerator electrodes, plasma sources, antennas, and microwave vacuum tubes. Research includes efficient energy conversion and storage techniques, high performance switching, and precision pulse shaping.

High voltage (kilovolts to megavolts) is associated with pulsed power systems, but some applications, like particle detectors, require continuously applied high voltage (not in the form of short pulses) and do not require high peak power. High voltage systems require careful design so that the electric fields created do not exceed the breakdown threshold of the dielectric (air, vacuum, plastic, etc.) which is between the high voltage electrode and ground. Electrostatic simulations and high voltage testing are used to qualify designs.

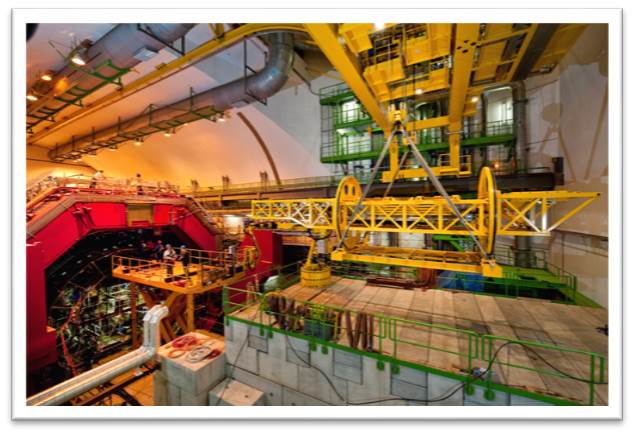

Large Physics Detectors

Physics detectors are developed to understand the evolution and structure of nuclear matter from the smallest building blocks, quarks and gluons, to the elements in the universe created by stars. The detectors detect, track, and identify the particles and sometimes operate as calorimeters, measuring the energy of radiation that is detected. We have the expertise to design, fabricate, and install large physics detectors and components that open new frontiers for the modern world.

Permanent / Hybrid Magnets

Multipole magnets are an essential component for steering and focusing charged particles in particle accelerators. Most commonly the magnets are electro-magnets, which are energized by current carrying conductors wrapped around low permeability poles. Alternatively these magnets can be made from permanent magnets or permanent magnets in conjunction with low permeability poles, or hybrid magnets. Permanent magnets and hybrid magnets operate without the use of power supplies and are typically more compact than electro-magnets. Permanent magnet and hybrid magnet field strength can be varied by movement of permanent magnet or low permeability elements. An example of an adjustable strength permanent magnet multipole are the chicane magnets used in the ALS. The field strength and field shape are controlled by rotating magnets.

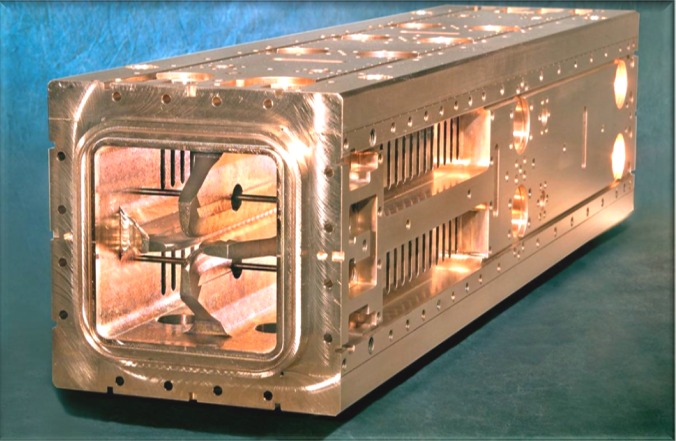

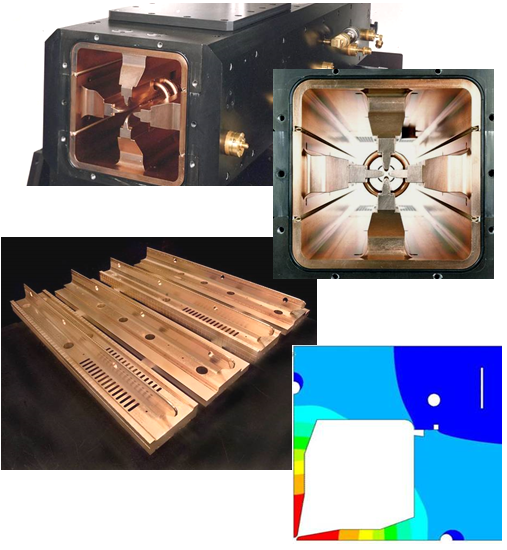

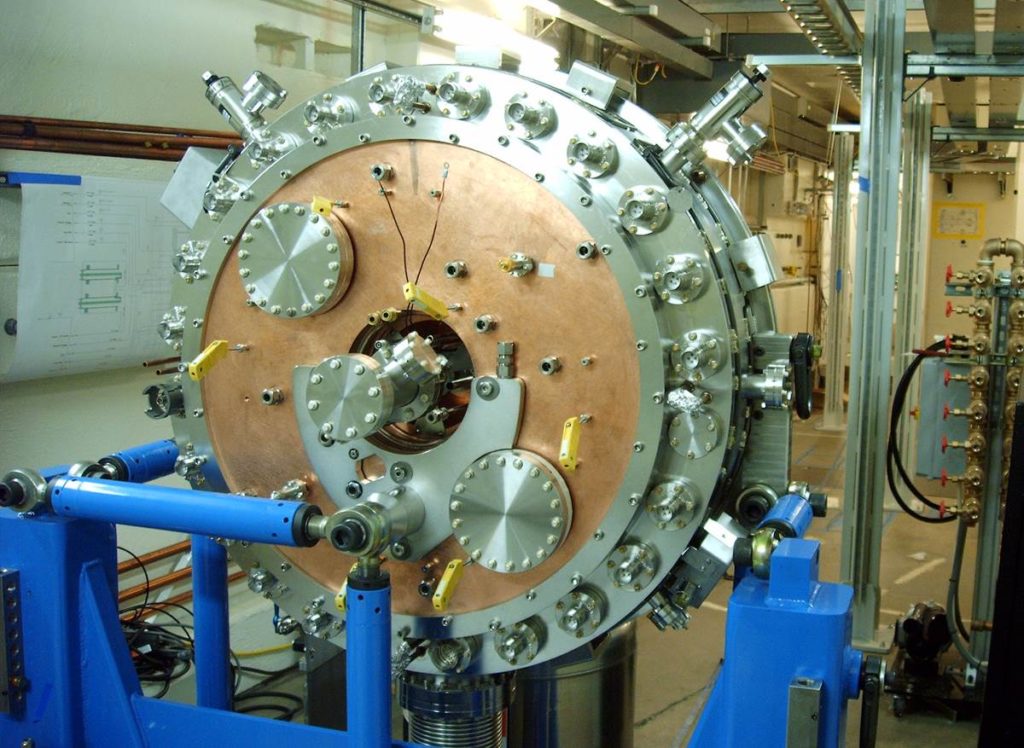

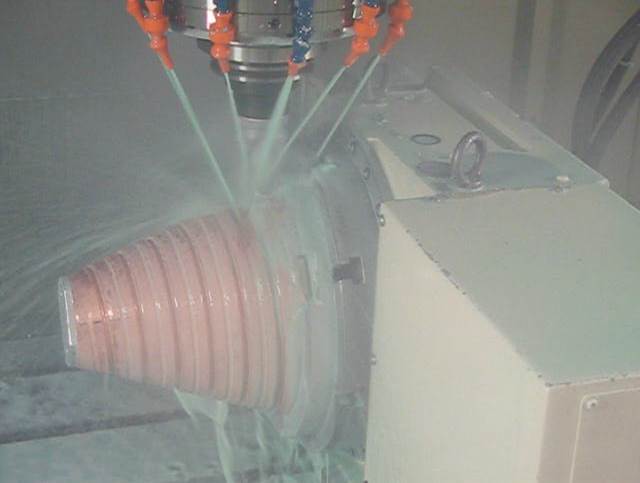

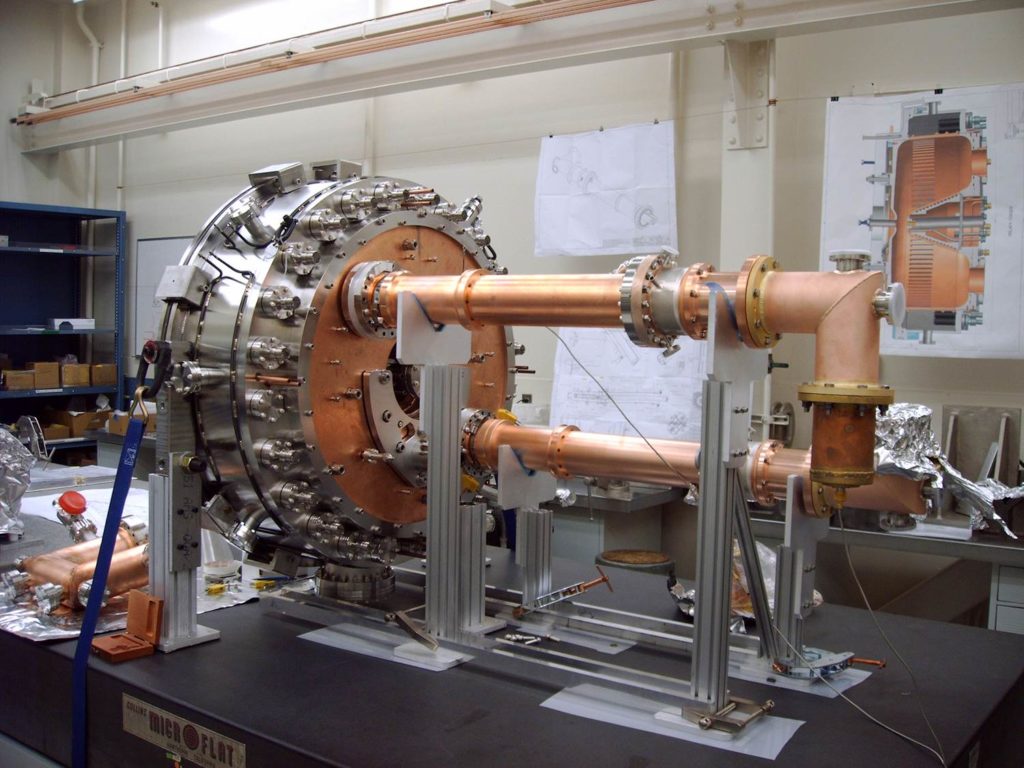

Mechanical Design & Analysis of RF Structures

The Berkeley Lab has developed methodology and expertise in the analysis, design and fabrication of RF cavities for a variety of applications. Numerous normal conducting copper cavities have been developed for use as accelerating structures for particle accelerator beamlines. We have extensive experience designing, building and operating both pillbox type cavities and radio-frequency quadrupoles (RFQ’s) that operate over a wide range of resonant frequencies. The primary software tools used for the design and analysis of the cavities are CST Microwave Studio and ANSYS. Fabrication of the cavities are carried out in our shops with specialized procedures such as hydrogen brazing, e-beam welding and cooling passage gun-drilling being provided by selected local vendors.

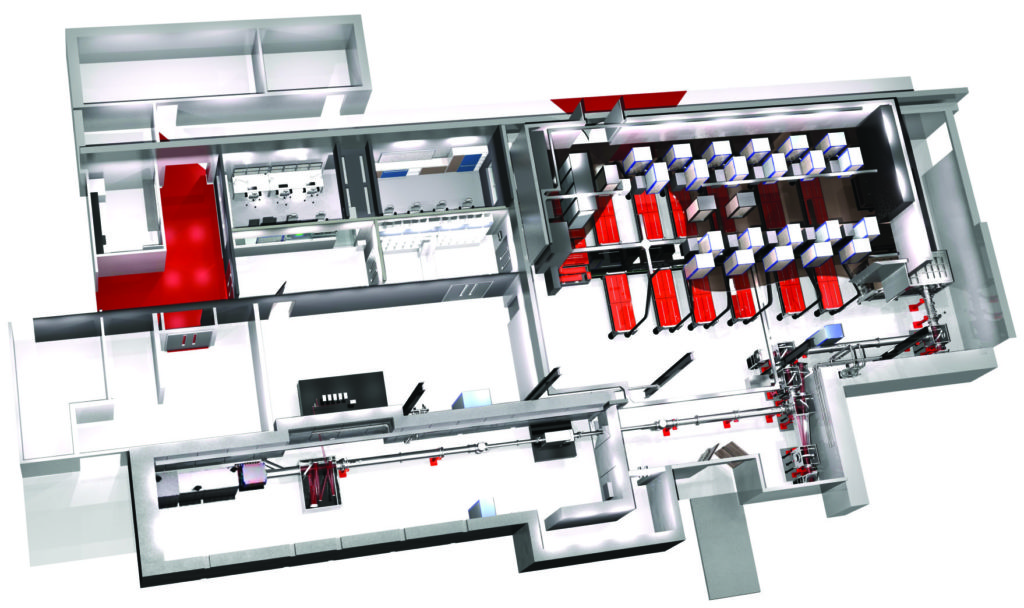

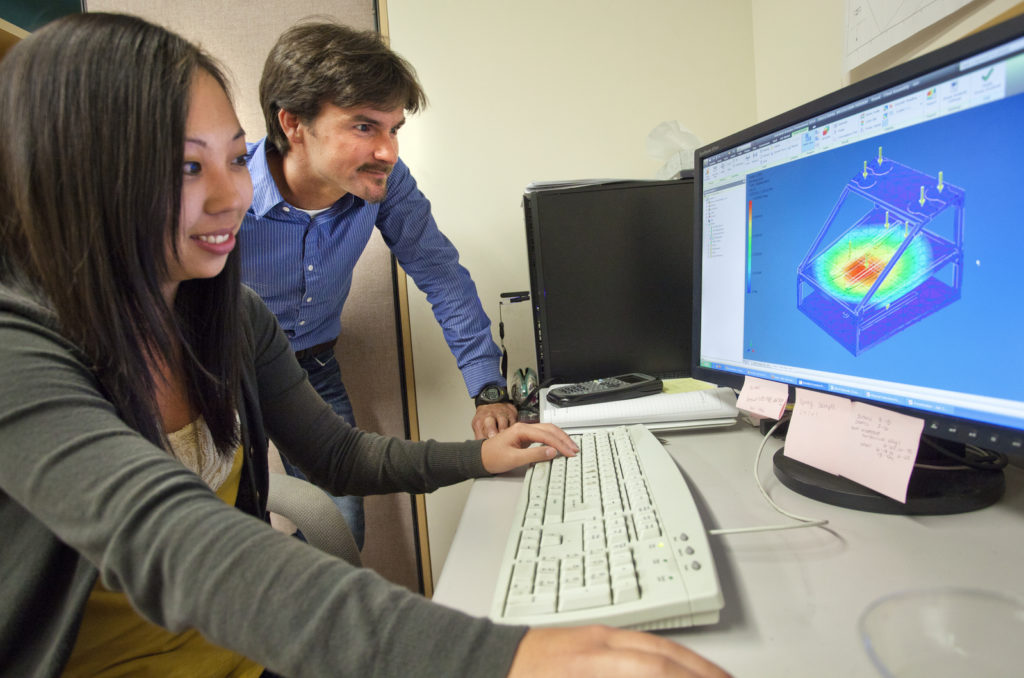

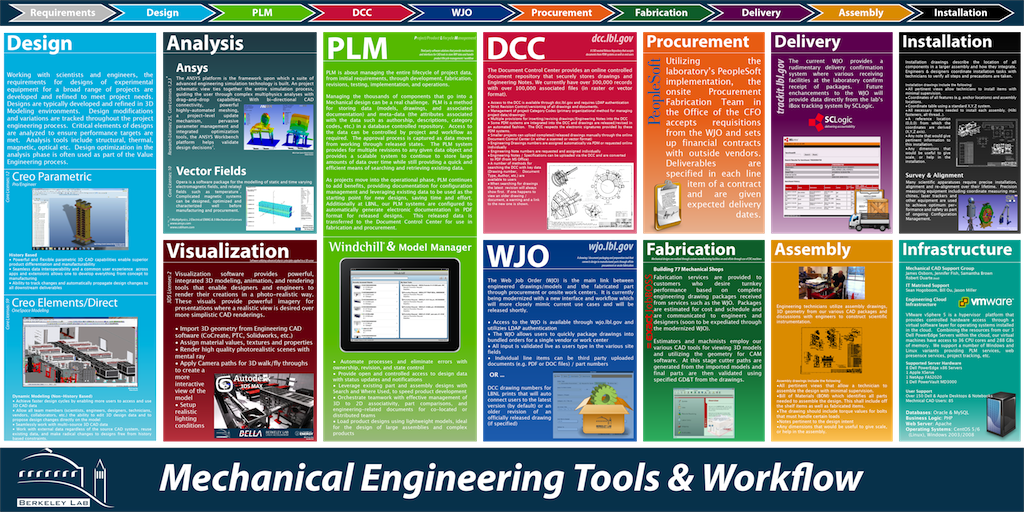

Mechanical Design

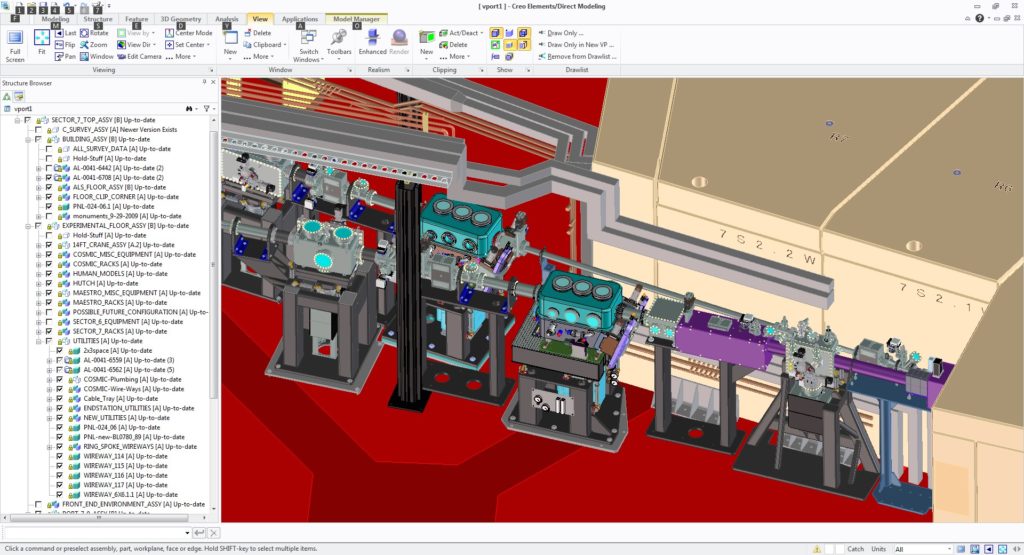

Mechanical CAD in the Engineering division consists of a suite of applications/processes that enable a workflow encompassing the entire design methodology. The process runs from the initial requirements given to our engineers and designers to the final product/assembly installed in our instruments. This includes requirements management, design, analysis, and visualization through to the documentation required for fabrication and procurement. Designs are modeled in various 3D CAD applications and the data generated from these tools are collected and managed in controlled repositories called Product Lifecycle Management systems. Document control is the final arbiter of released documentation and is utilized in the procurement and manufacturing of our designs.

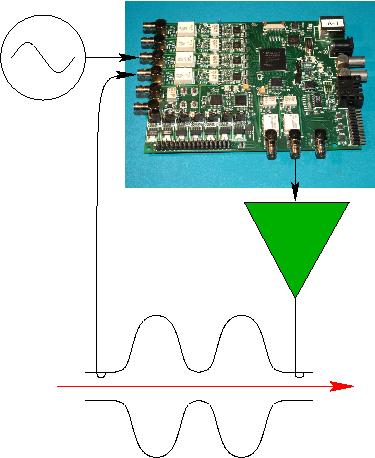

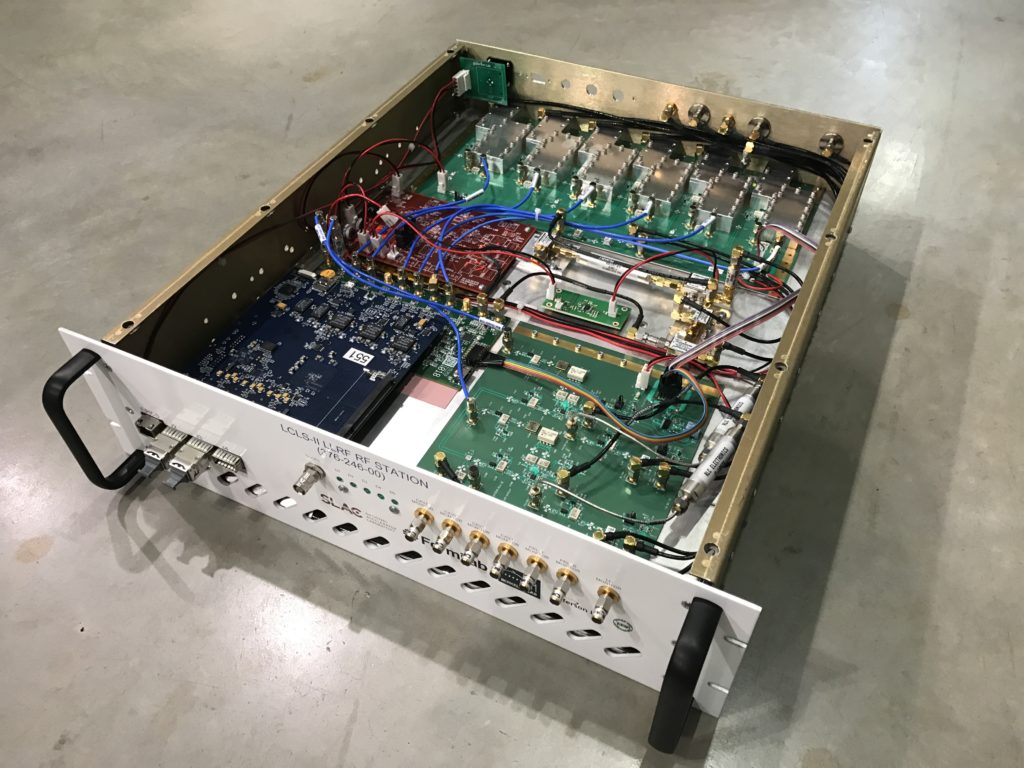

Low-Level Radio Frequency (LLRF) Control

We utilize Low-level Radio Frequency (LLRF) to control accelerator beamlines and are pioneers of implementing fully digital LLRF/RF controls. The high power sources that drive electromagnetic fields inside accelerating cavities must be precisely controlled against noise perturbation for optimal beam quality. To do this, the LLRF controller measures the magnitude and phase of a sample of the cavity field, and feeds back to the high power RF amplifier in hard real time. Typical feedback loop response times are 0.5 to 2.0 microseconds.

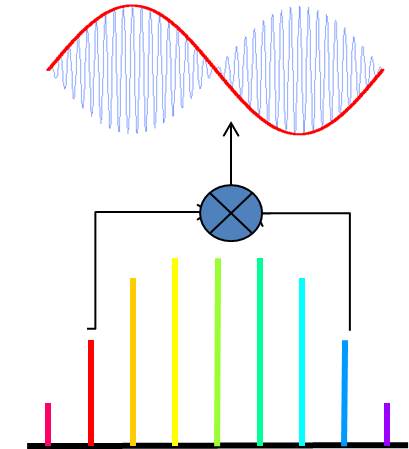

Achieving <0.02° of stability at 2856 MHz, we have applied this technology to the timing distribution system in the latest FEL (free electron laser) facilities, synchronizing remote lasers and RF references with combined jitter and long-term drift as low as 20 femtoseconds rms. Using Innovative techniques to reduce crosstalk and close-in phase noise, we have achieved short-term SRF cavity stability better than 0.01°. With well-designed digital (FPGA) programming, we have also demonstrated automated cavity turn-on and robust cavity operation in the presence of microphonics.

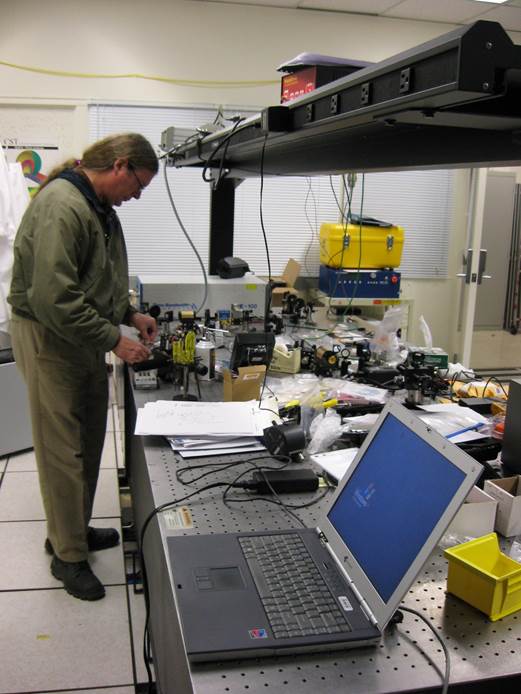

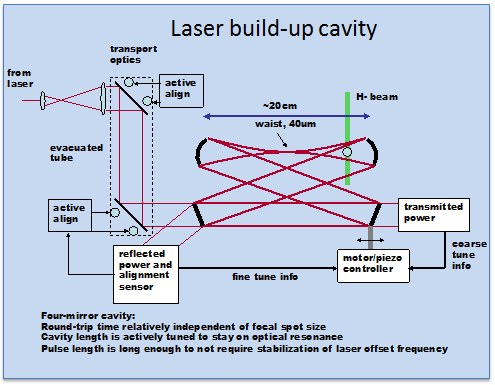

Laser systems

Light sources used for science are often complex arrangements of laser sources, amplifiers, passive and active optical devices, diagnostics, electronics and computers. Advanced designs produce light with previously unavailable characteristics, enabling new scientific research. Laser systems are also combined with X-ray sources to initiate physical processes and measure them. For instance, a high-average power, short pulse laser source was developed for materials science experiments on the Advanced Light Source (ALS).

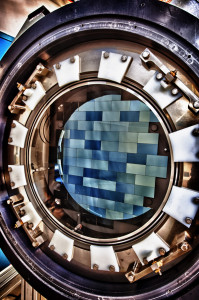

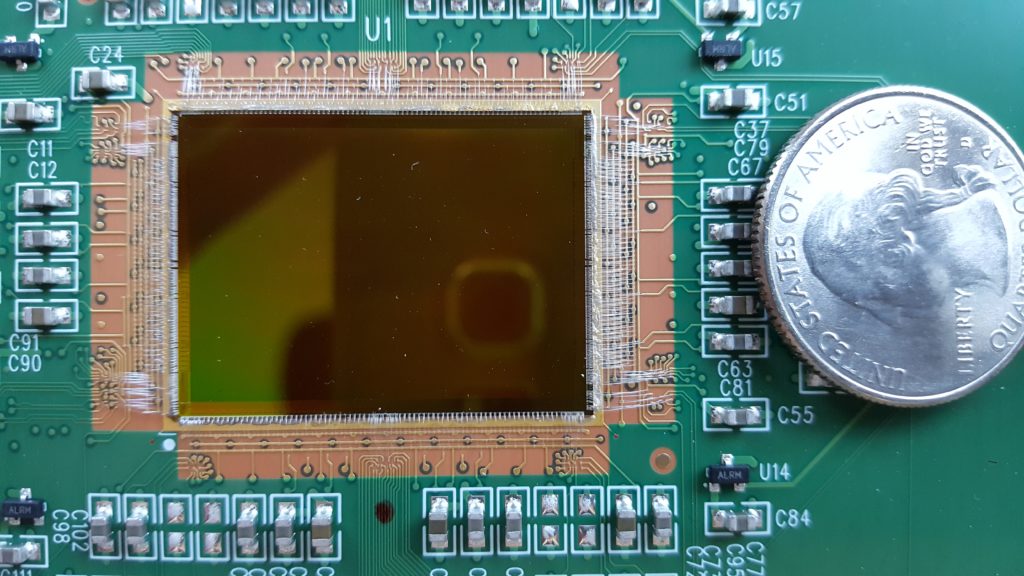

Imaging Detectors

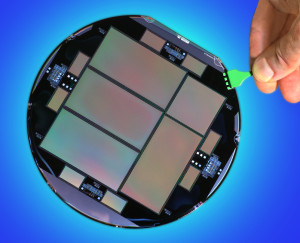

Imaging detectors such as charge-coupled devices (CCDs) are primarily used for astronomical observation and x-ray imaging. Our CCDs are noted for their exceptionally high, near-infrared sensitivity and capability to capture images billions of light years away. The Berkeley Lab MicroSystems Laboratory produces scientific CCDs for imaging and spectroscopic applications in astronomy as well as for the direct detection of x-rays at the Advanced Light Source.

The 570 Mpixel Dark Energy Survey camera located at the National Optical Astronomy Observatory Cerro Tololo Inter-American Observatory utilizes 74 fully depleted CCDs that were fabricated at Teledyne DALSA Semiconductor and the MicroSystems Laboratory. Fully depleted, 16 Mpixel CCDs are also in use in the Baryon Oscillation Spectroscopic Survey (BOSS) experiment and are planned for operation at the Mid-Scale Dark Energy Spectroscopic Instrument (MS-DESI).

The Dark Energy Survey camera is located at the Cerro Tololo Inter-American Observatory that is part of the National Optical Astronomy Observatory. CTIO is located in the Andes mountains in Chile. The project is called the Dark Energy Survey.

Silicon wafer containing CCDs used in DECam.

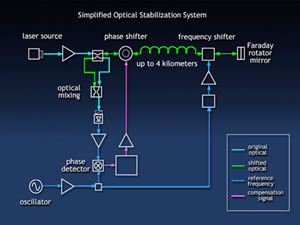

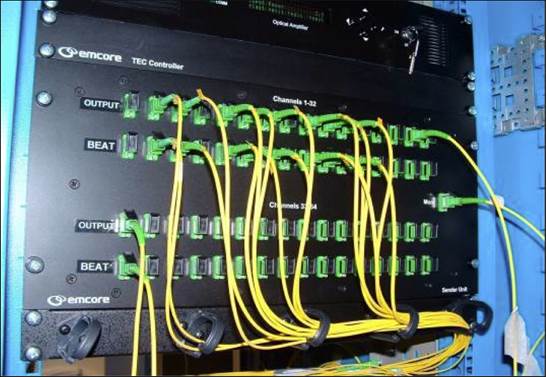

fs Timing and Synchronization

Scientific experiments which interact two or more short-duration events must synchronize them in time. Laser and X-ray light sources can now produce pulses with few-femtosecond (1 femtosecond = 0.00000000000001 seconds) or sub-femtosecond duration, requiring precise timing. It is possible to measure and control the timing of lasers with this precision, using stable RF and optical frequencies transmitted over fiber optics. A combination of optical and electronic technology has been developed to support short pulse X-ray and optical science at large user facilities.

Fabrication

Our fabrication expertise and facilities enable us to manipulate various materials to manufacture a wide range of components and structures using cutting-edge manufacturing techniques. We are able to produce components or features ranging from several microns to several meters in size using a broad range of fabrication technologies including: conventional machining, micro-machining, Electrical Discharge Machining, additive manufacturing, welding, sheet metal, ultra high vacuum cleaning, vacuum deposition, vacuum brazing, mechanical metrology, and precision alignment. Utilizing these technologies, we are able to repair and engineer various electronics, detectors, injectors, mechanical mechanisms, and various other structures and components to prototype and/or build apparatuses that support the science at the Berkeley Lab. In addition, our machine shops provide planning and estimating services to identify efficient alternatives to achieve your project objectives.

Visit our Engineering Shops & Laboratories page or contact us for more information.

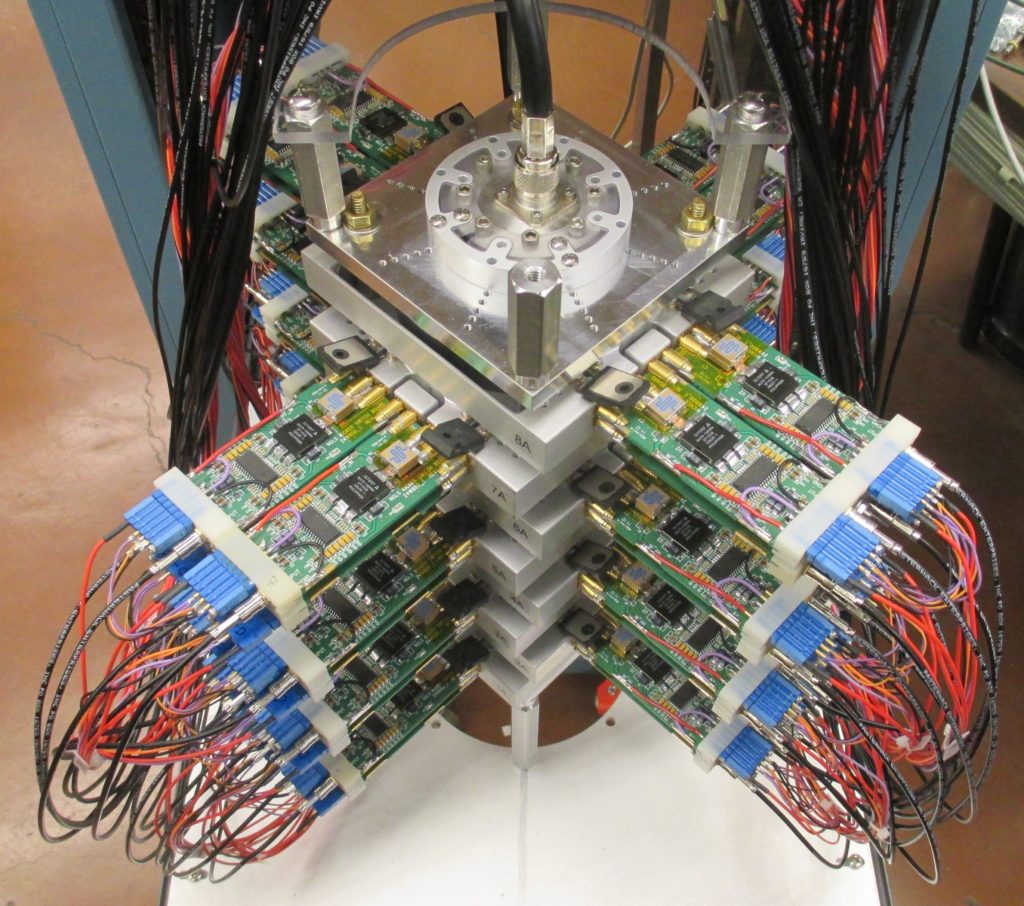

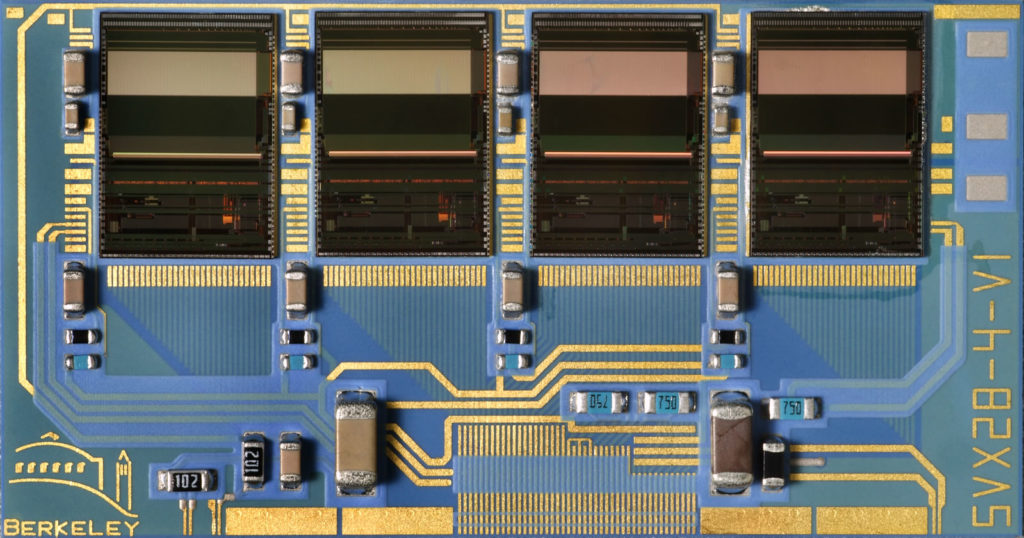

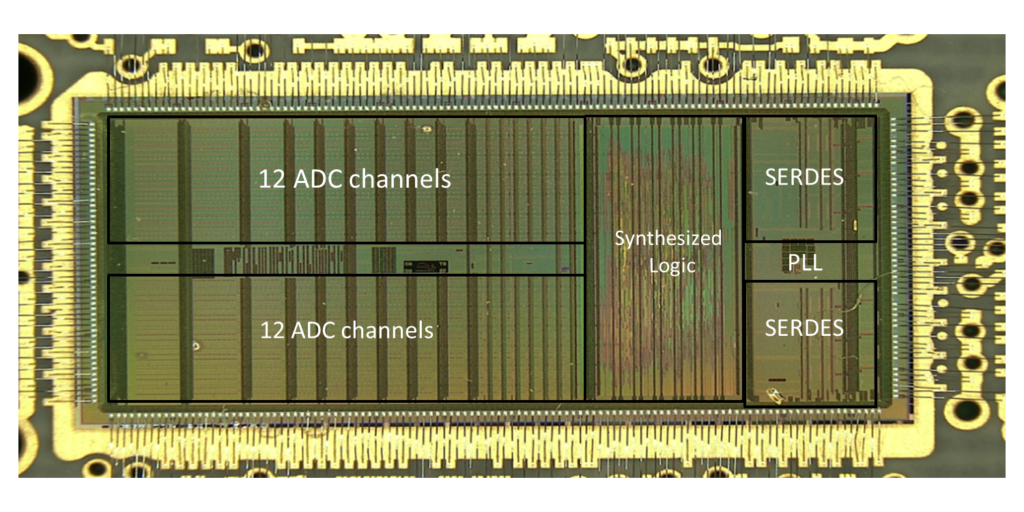

Custom Integrated Circuits

The LBNL IC Design Group delivers high-performance mixed-signal integrated circuits for a variety of applications, but specializes in integrated circuits for particle detector and scientific imager readout. We focus on providing high channel-count mixed-signal chips for extreme environments (e.g. high radiation, low temperature, or in-vacuum operation) where suitable commercial parts do not exist. Our core capabilities include ultra-low-noise analog front ends, high-performance data converters, CCD imager clock drivers, and CMOS active-pixel sensors for scientific imaging. We offer complete integrated solutions including power management, clocking, and serial digital data interfaces. We have design capabilities in a wide range of IC technologies including mixed-signal, SOI, and High-Voltage CMOS, and have delivered integrated circuits fabricated in CMOS process nodes from 3 μm down to 65 nm.

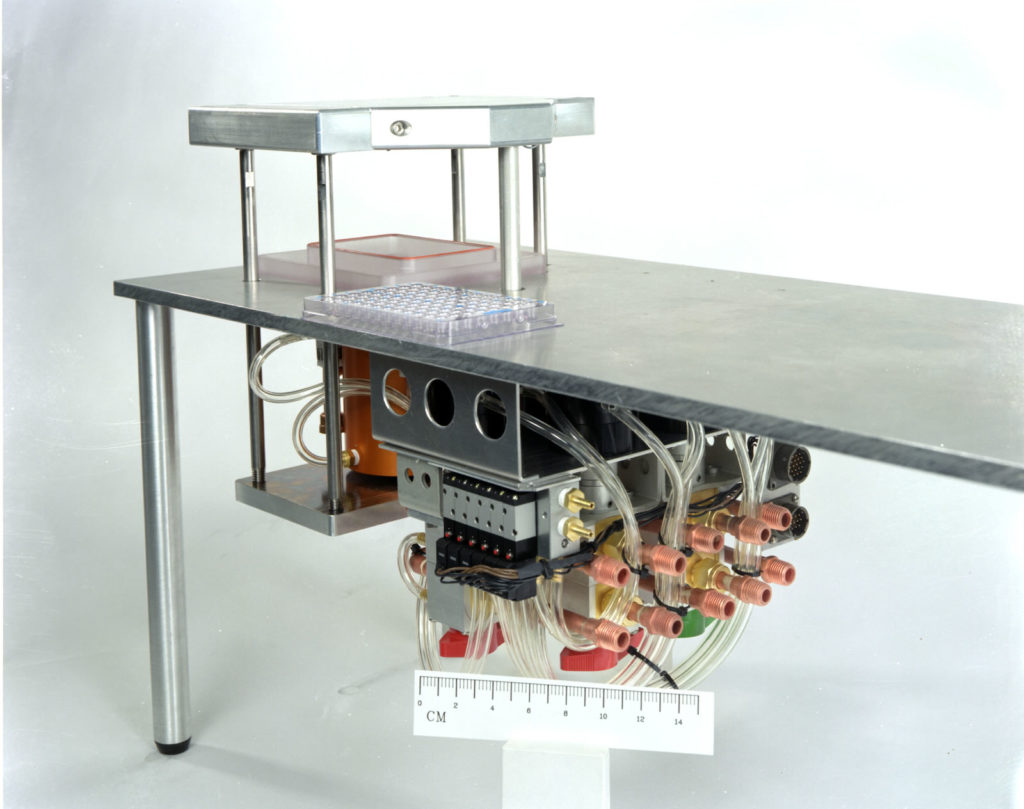

Bio-instrumentation

Our bio-instrumentation scientists and engineers develop analysis tools for life science and materials science research. They have made significant contributions to the Human Genome Project and developed a number of novel and enabling technologies for life- sciences. These tools include capillary array DNA sequencer, DNA/RNA microarray printer and scanner, high throughput and automated protein purification, protein crystallization and x-ray protein crystal screening systems, high throughput drug screening system, automated cancer cell-line growth and treatment system, integrated mass spectrometry for proteomics, phase-contrast technology for transmission electron microscopy. Recently, the scope has expanded to include development of high throughput and combinatorial technologies for rapid discovery of photo-electro-chemical materials for solar-fuel research and development of prototype solar-fuel generators. In general, this group is capable of collaborating with scientists in all fields (including industry) and developing novel and enabling technologies that give its collaborators competitive edge.

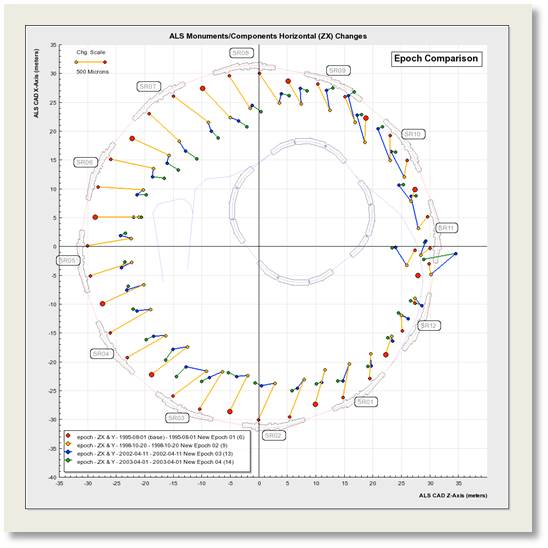

Survey & Alignment

The Survey & Alignment Group is responsible for the accurate positioning of accelerator and instrumentation components using precision surveying techniques and engineering methodologies. The capabilities include fiducialization, inspection, metrology and alignment. This group utilizes state of the art tools such as laser trackers, laser scanning & interferometry, digital levels, coordinate measuring machines, metrology arms and ground penetrating radar.