Pushing the boundaries of science requires the ability to fabricate and build instruments and tools that are novel, innovative, or one of a kind. The Engineering Division’s fabrication and manufacturing facilities are dedicated to creating these tools. These facilities provide a broad range of comprehensive, technically advanced manufacturing resources to the scientific divisions and user facilities of Berkeley Lab, with technical capabilities often not available from commercial vendors. In addition, the onsite shops allow for quick turnaround and collaborative process development for novel components.

The Composites Shop specializes in designing and fabricating high-performance carbon-fiber structures and precision-bonded assemblies (incorporating both metallic and composite components) for silicon tracking detectors and other specialized applications. The shop has provided global support and integrated low-mass cooling support for detecting elements for various silicon trackers for the DOE’s Offices of High Energy Physics and Nuclear Physics, installed around the world.

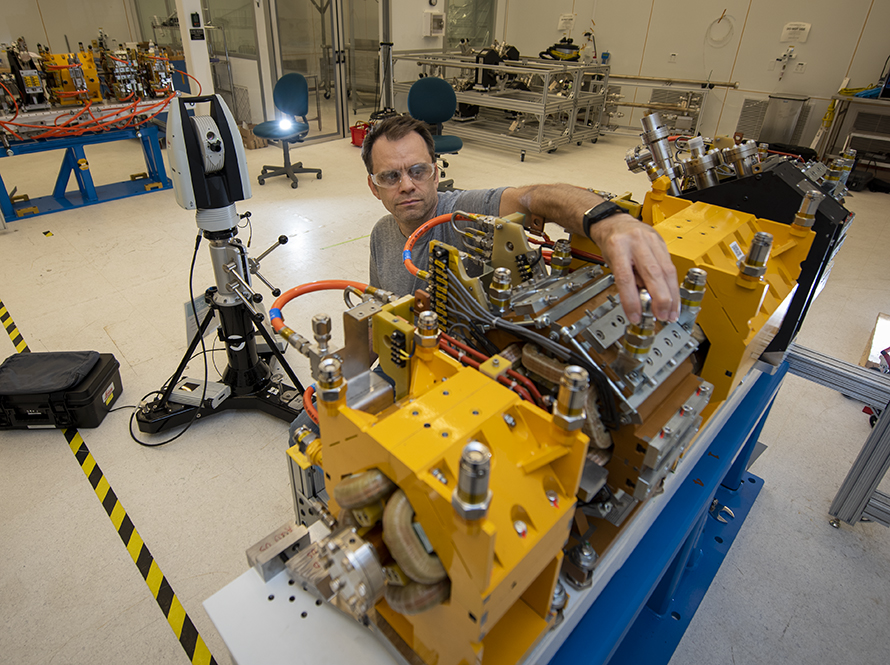

The precision measurement facility serves an essential function in QA and alignment of the unique instruments and assemblies produced by the Engineering Division.

Key areas of competency for our manufacturing engineering team are installation planning and final assembly coordination, which are critical functions for science projects. Our engineers support technical teams and technical procurement specialists by defining and overseeing the execution of large-scale installation efforts, such as the Advanced Light Source Upgrade (ALS-U), or complex component fabrication at outside companies to ensure integration and functionality of the technical delivery.

The manufacturing and assembly facilities focus on providing a broad range of technically advanced production resources to the scientific divisions and user facilities of Berkeley Lab. These resources provide a collaborative environment for the development of components and assemblies, in-house fabrication of complicated, multi-process, multi-level assemblies, shorter lead times than outside vendors, emergency fabrication, and repair.

The electronics maintenance and electronics installation shops provide round-the-clock operations and user assistance, spanning a diverse spectrum of technologies, including controls, radio frequency, and high-power electronics crucial for photon science activities.