Ergo Improvements Make Positive Impact

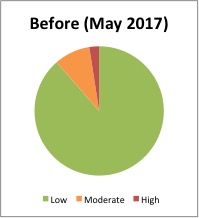

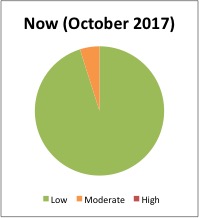

In FY17, computer ergonomic (ergo) exposure was the second highest recordable injury, accounting for 22% of the Laboratory’s recordable injuries. To address this problem head on, the Engineering Division Ergo Advocate Team has implemented a proactive approach to reducing ergo risks in the division.

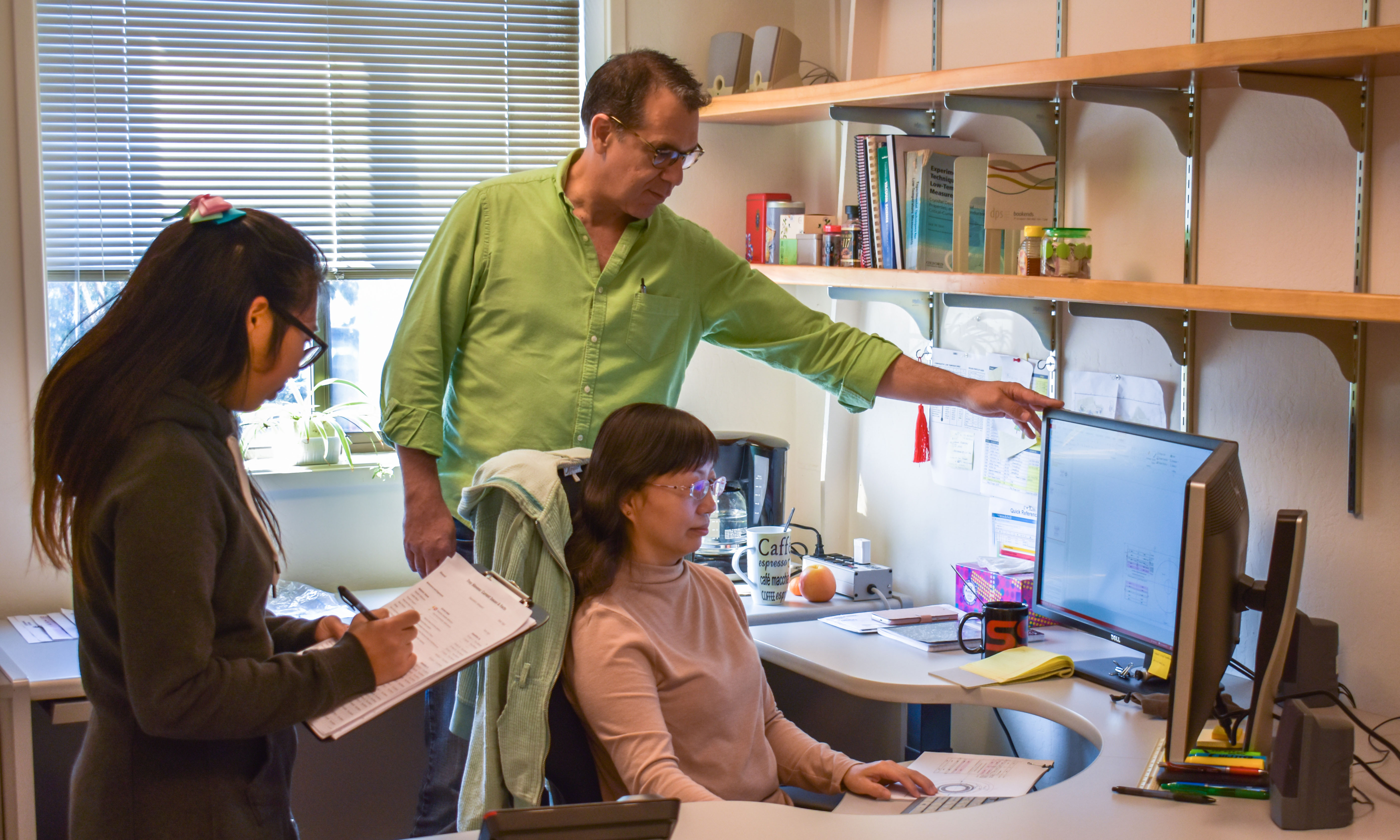

Each week since June, the ergo duo, Eva Pan and Marshall Granados, review ergonomics reports to prioritize and target employees identified as high and moderate risk for ergonomic injury. Starting with the individuals at the highest risk level and with the highest number of ergo issues, they initially conduct drop-in visits for a casual ergo safety discussion and to offer recommendations to reduce ergo risk. Working as a team, they are able to discuss issues with the employee, make and document observations, and make workstation adjustments during the visit. If a drop-in visit proves to be ineffective or inconvenient, they calendar a formal meeting with the employee. Each employee is visited at least twice to offer recommendations and monitor progress towards implementation and improvement of fatigue or discomfort.

Each week since June, the ergo duo, Eva Pan and Marshall Granados, review ergonomics reports to prioritize and target employees identified as high and moderate risk for ergonomic injury. Starting with the individuals at the highest risk level and with the highest number of ergo issues, they initially conduct drop-in visits for a casual ergo safety discussion and to offer recommendations to reduce ergo risk. Working as a team, they are able to discuss issues with the employee, make and document observations, and make workstation adjustments during the visit. If a drop-in visit proves to be ineffective or inconvenient, they calendar a formal meeting with the employee. Each employee is visited at least twice to offer recommendations and monitor progress towards implementation and improvement of fatigue or discomfort.

Since the implementation of this new approach to ergo risk management, high risk ergo instances have been eliminated and moderate instances have been reduced by 46%. Out of 245 employees, the percentage of low risk employees has increased from 89% to 95%. The team continues initiate contact and work with the remaining 5% of employees who remain at the moderate risk level, some of which have chronic ergo issues that are being actively managed.

Not only have the numbers improved, but actively managing ergo risks has also had a positive effect on employee morale. Employees have expressed appreciation that their well-being is being considered. One employee stated, “I’m not used to people caring about me, only my output and the work that I do.”

While doing an assessment, the ergo duo discovered that the ergo risk they were assessing for one employee actually impacted the entire control room used by several employees in multiple divisions. Six workstations used the same obsolete, unadjustable chairs that required users to hunch to perform their work. In some cases, the employees spent more time at these workstations than they spent at their desks. In result of actions prompted by the initial ergo assessment of one employee, all six workstations are scheduled to be upgraded to current ergo standards, eliminating the ergo hazard for the group.

Though this project began as a way to reduce the ergo risk in the division, the benefits have reached beyond what was anticipated. The team approach promotes continuous progress and the partner-accountability helps to maintain consistency. Additionally, safety and morale of employees has improved and spills over into adjacent workspaces. With this new proactive approach to managing ergo risks, we hope to eliminate preventable ergonomic injuries in the division.

Schedule Photo Session

Engineering Division employees are encouraged to get a head shot taken. Employee photos are used for various purposes including: photo boards, seating charts, org charts, presentations, etc. Use the link below to schedule an appointment to have your photo taken.

LUX-ZEPLIN (LZ)

Sanford Underground Research Facility (SURF), Lead, South Dakota

The LUX-ZEPLIN (LZ) experiment utilizes 7 tonnes of active liquid xenon to search for xenon nuclei that recoil in response to collisions caused by an impinging flux of dark matter particles known as WIMPs (Weakly Interacting Massive Particles). The experiment will be located nearly 1 mile underground in the Sanford Underground Research Facility (SURF) in Lead, South Dakota. The active liquid xenon is configured in a cylinder 1.5 meters in diameter and height, with an applied electric field to form a TPC (Time Projection Chamber).

Source: http://lz.lbl.gov/detector/

ALS-U

Advanced Light Source (ALS), Lawrence Berkeley National Laboratory, Berkeley, CA

ALS-U is a planned upgrade of the Advanced Light Source (ALS) at Berkeley Lab that will provide revolutionary x-ray capabilities. The ALS has been a global leader in soft x-ray science for more than two decades. Recent accelerator physics breakthroughs now enable the production of highly focused beams of soft x-ray light that are up to 1000 times brighter than that of the existing ALS. Applying this technology at the ALS will help us to better understand and develop the new materials and chemical systems needed to advance our energy, economic, and national security needs in the 21st century, securing the United States’ world scientific leadership for decades to come.

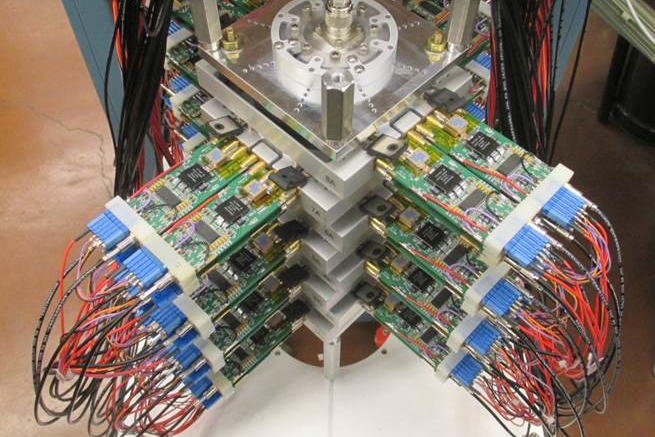

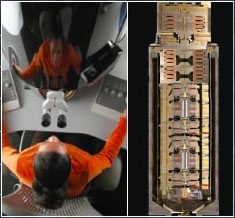

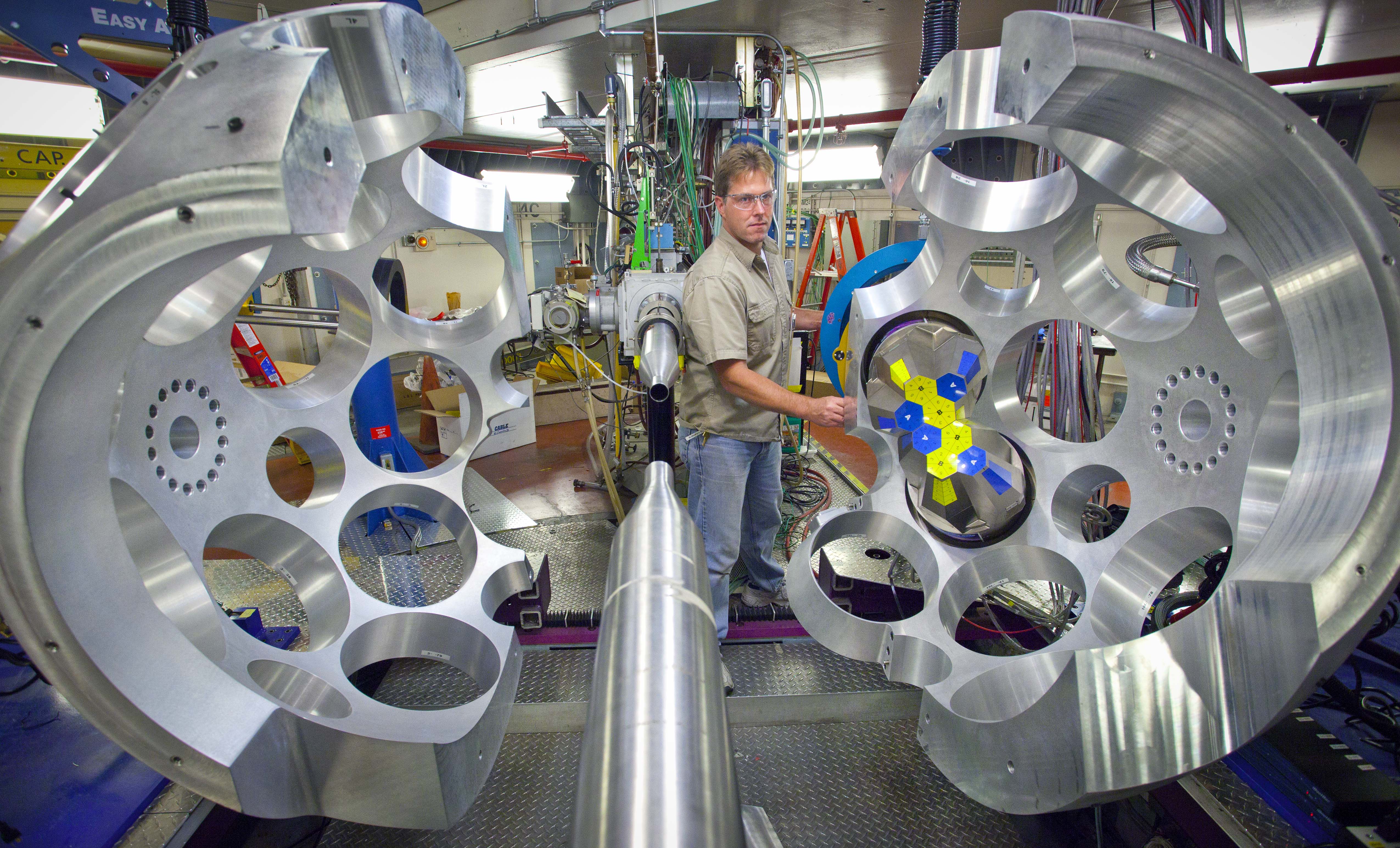

STAR Heavy Flavor Tracker

Brookhaven National Laboratory, Upton, NY

The Heavy Flavor Tracker (HFT) is a vertex detector which is part of the STAR (Solenoid Tracker at RHIC) detector located at the RHIC (Relativistic Heavy Ion Collider) accelerator. The HFT detector is designed to detect particles containing heavy quarks by measuring their extremely short decay vertexes. It consists of 4 silicon detection layers; the inner two layers are PXL, followed by IST and SSD as the outer layer. PXL uses novel pixilated sensors with high resolution and low mass that achieve breakthrough performance results. IST and SSD are used to point the tracks between PXL and the STAR TPC (Time Projection Chamber). Scientists and engineers at Berkeley Lab have played a major role in the design of both PXL and SSD.

More Info:

http://newscenter.lbl.gov/2014/02/18/heavy-flavor-tracker-for-star/

http://science.energy.gov/np/highlights/2015/np-2015-03-a/

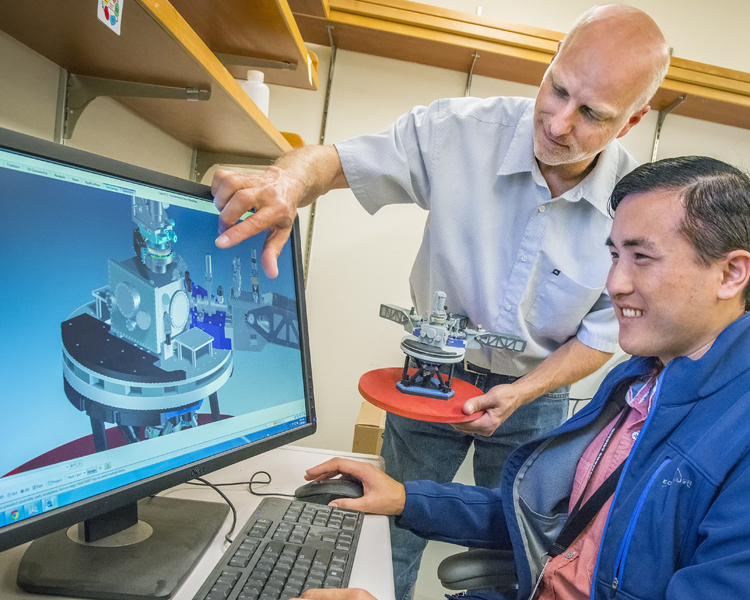

Pictured: Berkeley Lab Engineers, Thorsten Stezelberger and Luis Ardila-Perez

Photo Credit: Jim Thomas, SSD subsystem manager

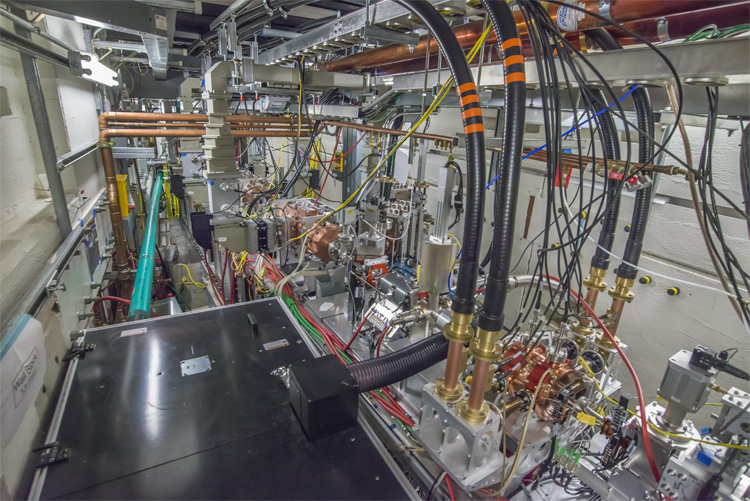

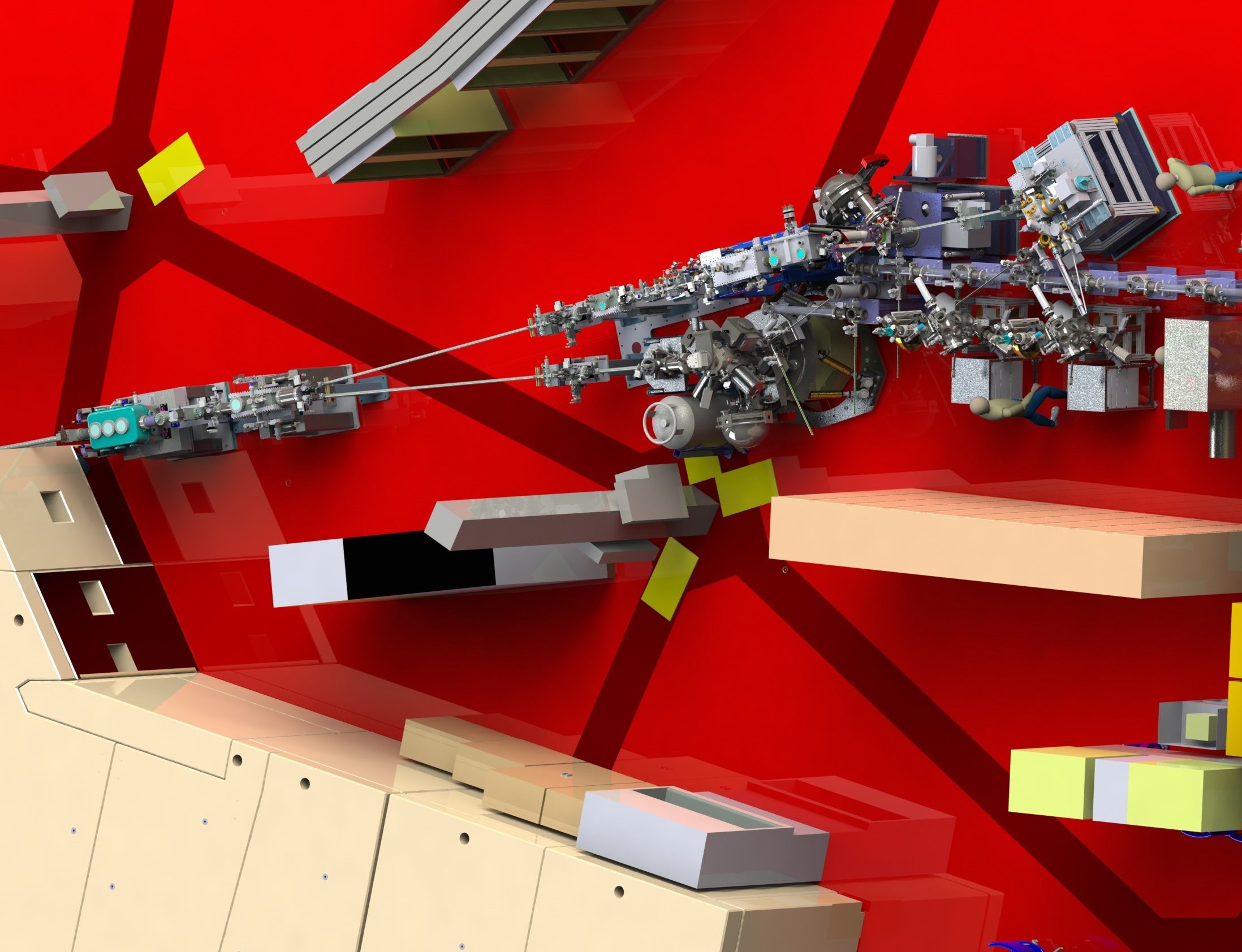

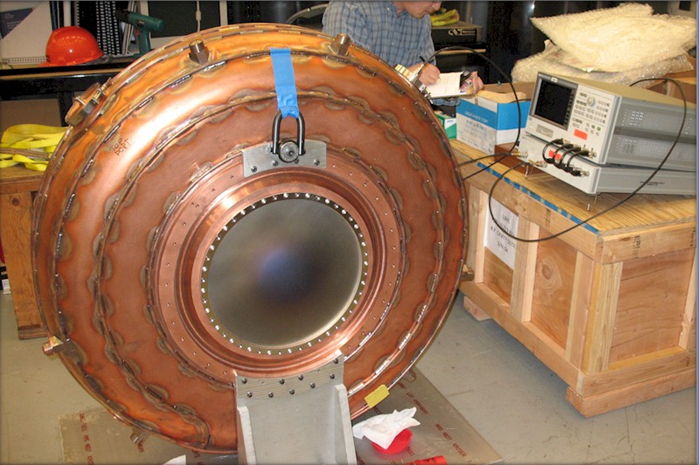

APEX

Advanced Light Source (ALS), Lawrence Berkeley National Laboratory, Berkeley, CA

The Advanced Photo-injector EXperiment (APEX) is dedicated to demonstrating the capability of an electron injector based on a new concept RF gun developed at Berkeley Lab to deliver the beam quality required by next generation free electron laser (FEL) facilities. The APEX gun is a normal-conducting continuous wave (CW) RF gun where electrons are generated by laser-induced photo-emission on high quantum efficiency (QE) cathodes. The electrons are subsequently accelerated up to the nominal energy of 750 keV. The low frequency makes the resonator size large enough to lower the power density on the cavity walls at a level that conventional cooling techniques can be used to run in CW mode, while maintaining the high accelerating fields required for the high brightness performance. In addition, the low frequency allows to use large apertures on the cavity walls without significant field distortion, therefore enabling efficient vacuum pumping and prolonging the lifetime of the sensitive high QE photo cathodes. The gun cavity resonates at 186 MHz, the 7th sub-harmonic of 1.3 GHz or the 8th sub-harmonic of 1.5 GHz, the two dominant superconducting linac technologies for next generation FEL facilities.

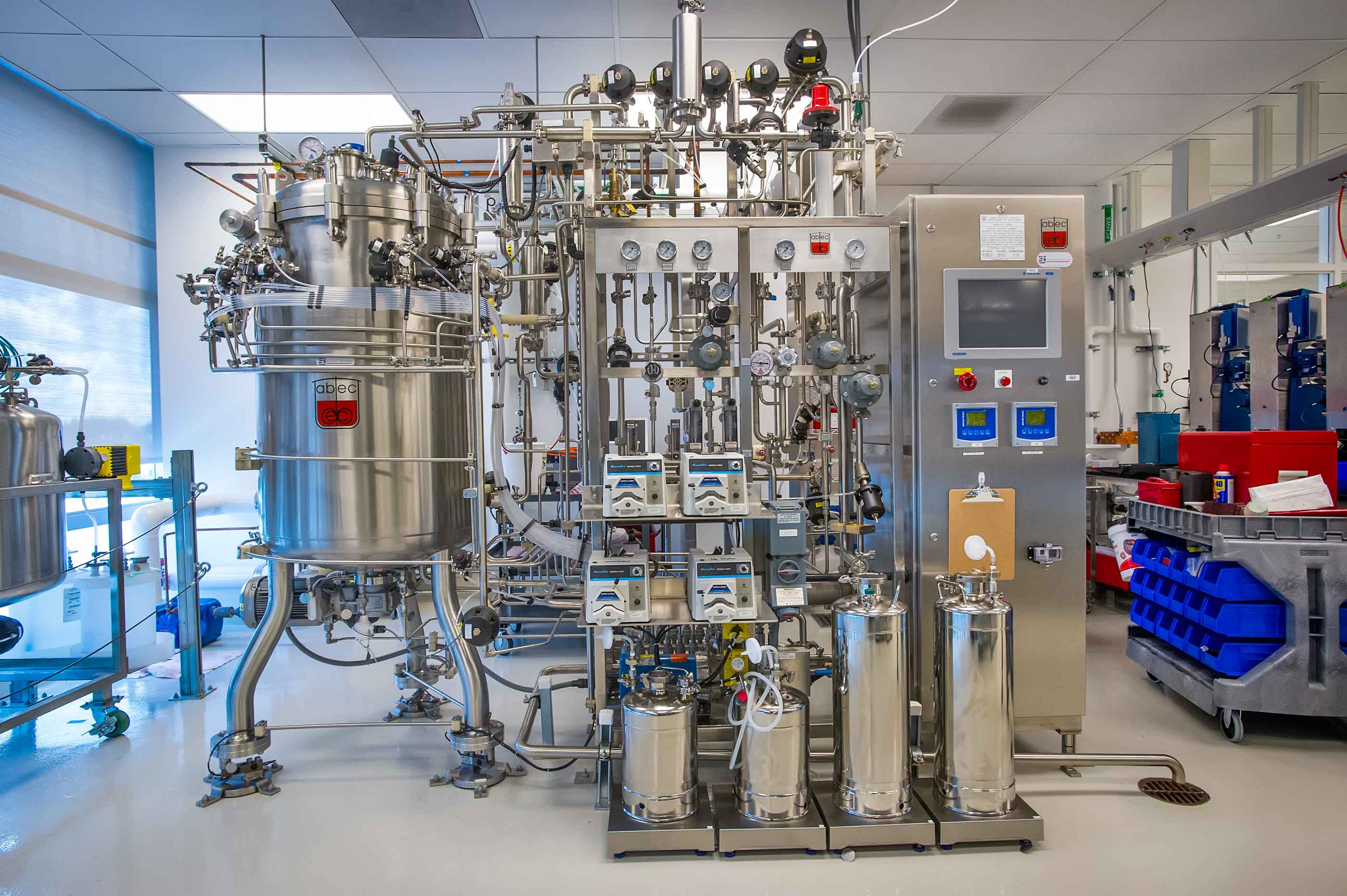

ABPDU Advanced Technologies

Advanced Biofuels Process Demonstration Unit (ABPDU) – Lawrence Berkeley National Laboratory, Emeryville, CA

ABPDU enables early stage advanced biofuels, biomaterials, and biochemicals product and process technologies to successfully scale from the lab to commercial relevance. The facilities at ABPDU are constantly adapted and new process algorithms developed to support various client and project requirements. The Engineering Division manages a number of electronic and mechanical engineering endeavors including developing and maintaining data and control systems, designing automation, monitoring environmental compliance, and modifying custom equipment (i.e., fermenters and biological reactors) to perform specialized processes. The advanced customization engineered at the ABPDU enables the program to offer unique capabilities for advanced research in bioproduction.

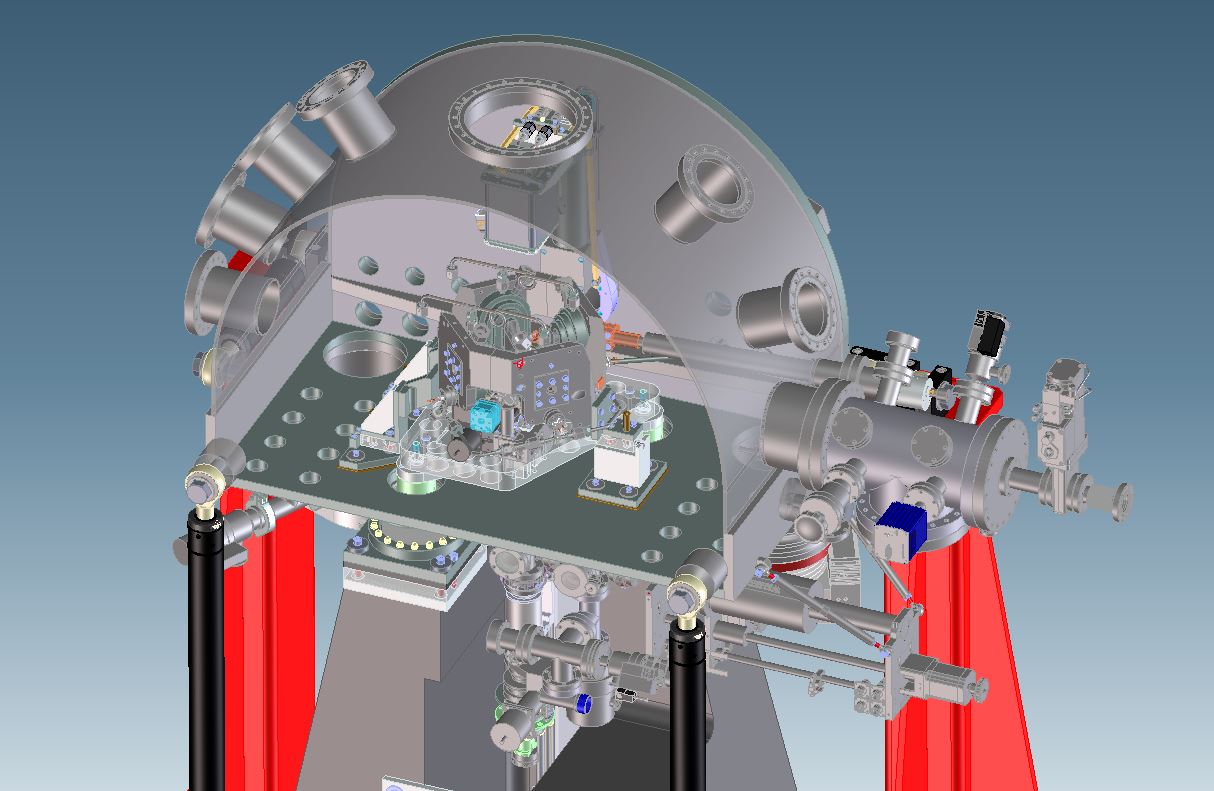

ALS qRIXS Endstation

Advanced Light Source – Lawrence Berkeley National Laboratory, Berkeley, CA

qRIXS is a novel endstation for momentum-resolved resonant inelastic x-ray spectroscopy studies the elementary excitations in three-dimensional correlated materials. The spectrometer covers a large energy range in the soft x-ray regime and is designed to be compact and flexible. It can accommodate up to five modular spectrometers to cover a large horizontal angular range simultaneously. Berkeley Lab Engineering Division designed and fabricated the endstation.

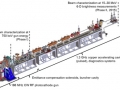

ALS MAESTRO Beamline 7.0.2

Advanced Light Source – Lawrence Berkeley National Laboratory, Berkeley, CA

MAESTRO at 7.0.2 is a beamline at the Advanced Light Source that advances angle-resolved photoemission spectroscopy for the study of electronic structure on the mesoscale regime, covering a photon energy range of 20-1000 eV with a resolving power of 20,000-30,000. The beamline is coupled to unique sample preparation and characterization facilities connecting all of the endstations. Berkeley Lab Engineering designed, built and installed the beamline and insertion device.

LCLS-II

Linac Coherent Light Source II (LCLS-II) – SLAC National Accelerator Laboratory Stanford University, Menlo Park, CA

LCLS-II is the upgrade of the Linac Coherent Light Source (LCLS) national user facility. LCLS is a powerful x-ray laser that enables exploration of atomic motion and changes in chemical bonds. The upgrade will add two new X-ray laser beams and expand the capacity for more instruments and research experiments. Berkeley Lab is leading the design and production of the injectors and undulators for the facility upgrade.

NDCX-II

Lawrence Berkeley National Laboratory, Berkeley, CA

NDCX-II, the second generation Neutralized Drift Compression Experiment, is an unusual special-purpose particle accelerator designed to produce a high-quality, dense ion beam that can be used to inform and guide the design of major components for heavy-ion fusion energy production. The Berkeley Lab Engineering Division designed and fabricated the high voltage injectors and accelerator structures and conducted the electrostatic simulation and analysis for the NDCX-II project.

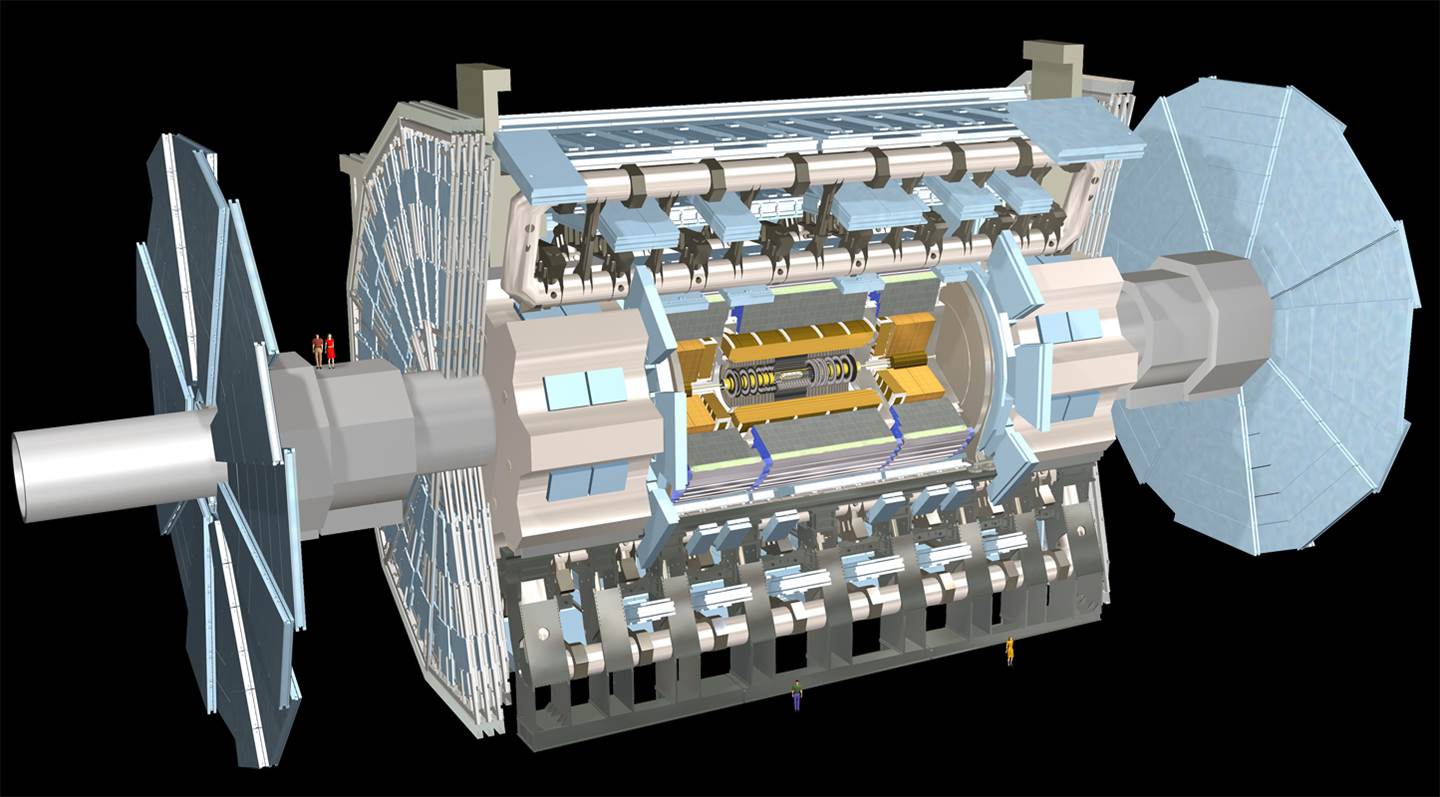

ATLAS

CERN, Meyrin, Switzerland

ATLAS is a large, 7,000 ton, multi-purpose detector at the Large Hadron Collider that is used to conduct particle physics experiments that seek new discoveries in the Universe using head-on collisions of protons of extraordinarily high energy. Critical of the elements including data acquisition electronics and silicon detector modules were designed and fabricated by Berkeley Lab’s Engineering and Physics Divisions.

ALICE

CERN, Meyrin, Switzerland

Physics detectors are developed to understand the evolution and structure of nuclear matter from the smallest quarks and gluons to the elements in the Universe created by stars. The ALICE Detector at CERN was designed to open a new high-energy frontier in the physics of ultra high-density hadronic matter and the Quark Gluon Plasma (QGP). The Berkeley Lab designed the Electromagnetic Calorimeter and fabricated 18 supermodules weighing 8 tons each.

IceCube

Amundsen–Scott South Pole Station, Antartica

IceCube is a neutrino detector/telescope buried over a mile beneath the Antarctic ice. The clear ice, stable conditions, and low background radiation make this location ideal for the telescope to look down and through the earth, opening a new window into the Universe. The IceCube observatory consists of 5,160 basketball-sized light detectors called Digital Optical Modules (DOMs), which were conceived and largely designed at Berkeley Lab.

TEAM

Transmission Electron Aberration-Corrected Microscope TEAM – Berkeley, CA

Electron microscopes can be used to observe extremely fine details of the inner-structure of materials.Transmission Electron Aberration-Corrected Microscope (TEAM) is a new generation microscope that explores nanometer-scaled structures and chemistry to characterize the dynamics of atoms that form various structures and materials.

LHC

MICE

Rutherford Appleton Laboratory (RAL), UK

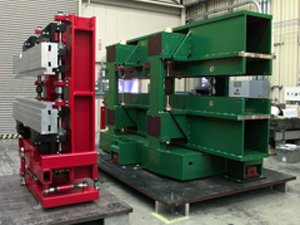

The Muon Ionization Cooling Experiment (MICE) is a high-energy physics experiment formed to demonstrate ionization cooling in a short section of a realistic cooling channel using a muon beam. The Berkeley Lab is responsible for designing and procuring the RF, RF cavities, superconducting magnets, conducting the thermal and structural analyses, and designing the Spectrometer Solenoid modules.

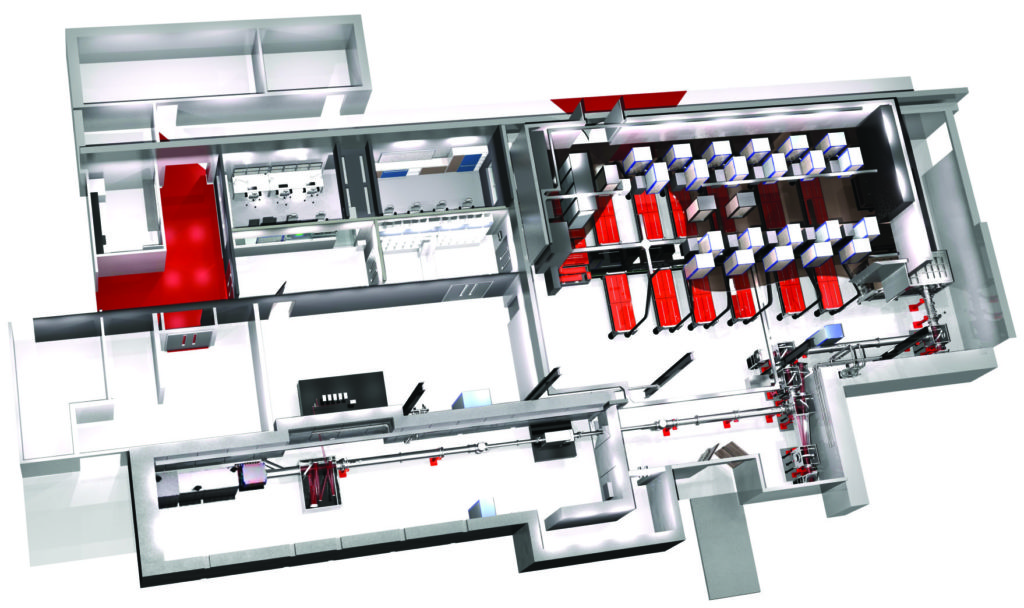

BeLLA

Lawrence Berkeley National Laboratory, Berkeley, CA

Berkeley Lab Laser Accelerator (BeLLA) is a world-record-setting laser system and state-of-the-art scientific facility for the advancement of laser plasma acceleration research. In 2014, the project won a DOE Secretary’s Achievement Award “for outstanding ingenuity and exceptional project performance.” The Engineering Division was responsible for the project management and all of the opto-mechanical systems, electrical and controls systems, and the site and systems integration of the BeLLA project.

GRETINA

88-Inch Cyclotron, Lawrence Berkeley National Laboratory, Berkeley, CA

GRETINA (Gamma-Ray Energy Tracking In-beam Nuclear Array) is a gamma-ray detector to study the structure and properties of atomic nuclei. It is built from large crystals of hyper-pure germanium and it uses the concept of gamma-ray energy tracking. GRETINA was constructed at the Berkeley Lab’s 88-inch Cyclotron and completed two yearlong campaigns at MSU’s National Superconducting Cyclotron Laboratory (NSCL) and ANL’s Argonne Tandem LINAC Accelerator System (ATLAS). It is presently in another experimental campaign at NSCL. GRETINA is the first stage of the full Gamma-Ray Energy Tracking Array (GRETA).

ALS Cosmics Scattering Endstation

Advanced Light Source – Lawrence Berkeley National Laboratory, Berkeley, CA

The COSMIC Scattering Endstation is an endstation focusing on understanding the nanoscale organization of complex materials using coherent soft x-ray scattering techniques. It is installed at one of two branches on the Coherent Scattering and Diffraction Microscopy (COSMIC) beamline. Berkeley Lab designed and fabricated the endstation.

Assembly Shop

The assembly shop is staffed with Mechanical Technicians that offer a wide range of technical services. The services include vacuum leak inspection, laser engraving, mechanical assembly and testing. For more information and capabilities please contact Lucian Sweitzer at 510-486-7680. To submit work requests please email assemblyshop@lbl.gov

Qualified Electrical Worker (QEW) Support

Qualified Electrical Worker Support:

The Engineering Division has QEWs designated to assist with the fabrication, modification and repair of Laboratory electrical equipment in accordance with our Electronic Equipment Build Standards. Schedule the support of a QEW via one of the following methods:

- Complete request form: https://app.smartsheet.com/b/form?EQBCT=cb6e45c71893442b9f614aa731513f11

- Email request to: qewhelp@lbl.gov

- Call x6222

- All Berkeley Lab unlisted (not UL or NRTL approved) electrical equipment must be inspected and approved before it can be used.

- All LBNL fabricated or modified listed electrical equipment must be inspected and approved before it can be used.

- See PUB 3000, Chapter 14 for details about Berkeley Lab’s Electrical Equipment Safety Program.

- Schedule an inspection BEFORE using unlisted or modified equipment via email: eesp@lbl.gov

___________

Background:

On October 13th, 2014 the Berkeley Lab Director wrote Division Directors and Division Deputies to emphasize the importance of electrical safety in the conduct of scientific research.

The Laboratory continues to expect that all staff understand and employ these fundamental electrical safety practices:

- Do not perform any electrical work

- Report unsafe equipment to your supervisor

- Enlist the support of a Qualified Electrical Worker (QEW) for all electrical work

- Lockout and Test Before Touch

- Establish and control the workspace

- Plan and control the work

- Correct unsafe behaviors and conditions

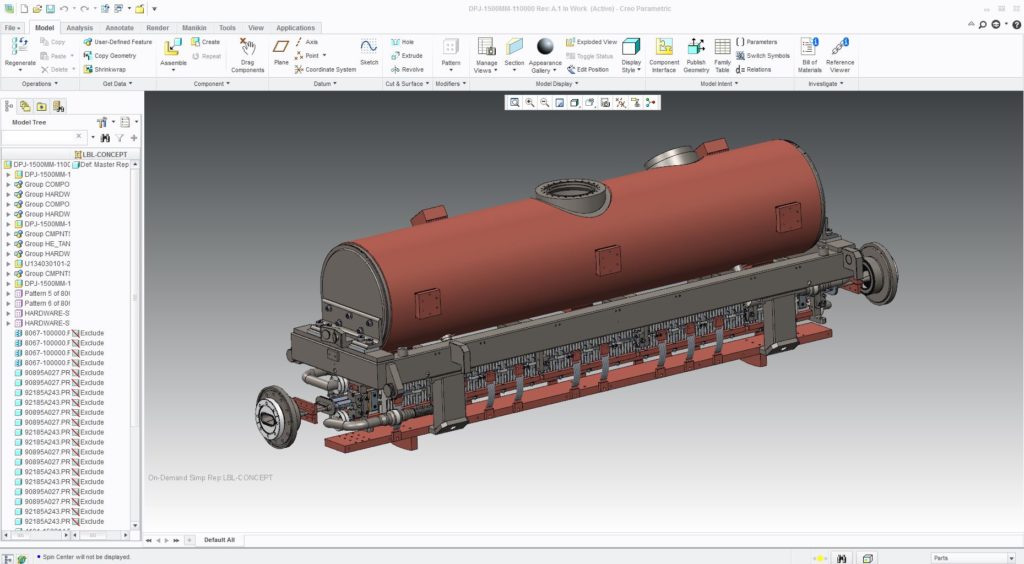

CAD System Software

Engineering develops software to support Computer Aided Design and Document Management. While most of the main applications are commercial, frequently custom software is required to tie systems together and create convenient user interfaces that implement Engineering CAD business models.