Advancing science by design

The Engineering Division provides essential technical expertise and transformative technologies that power scientific discovery. The Division creates innovative tools, instruments, and solutions to further scientific research, contributing to the Department of Energy’s mission to study new materials, address energy and environmental challenges, and advance fundamental science.

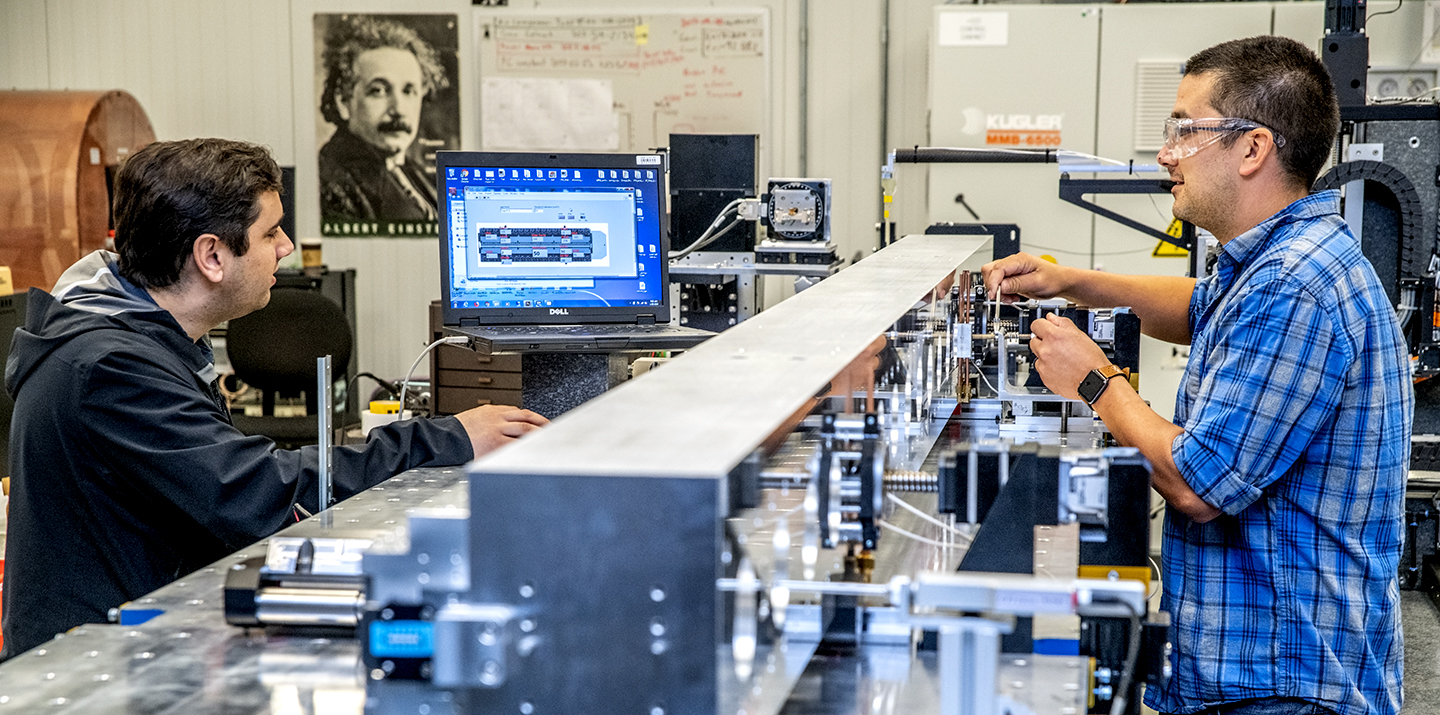

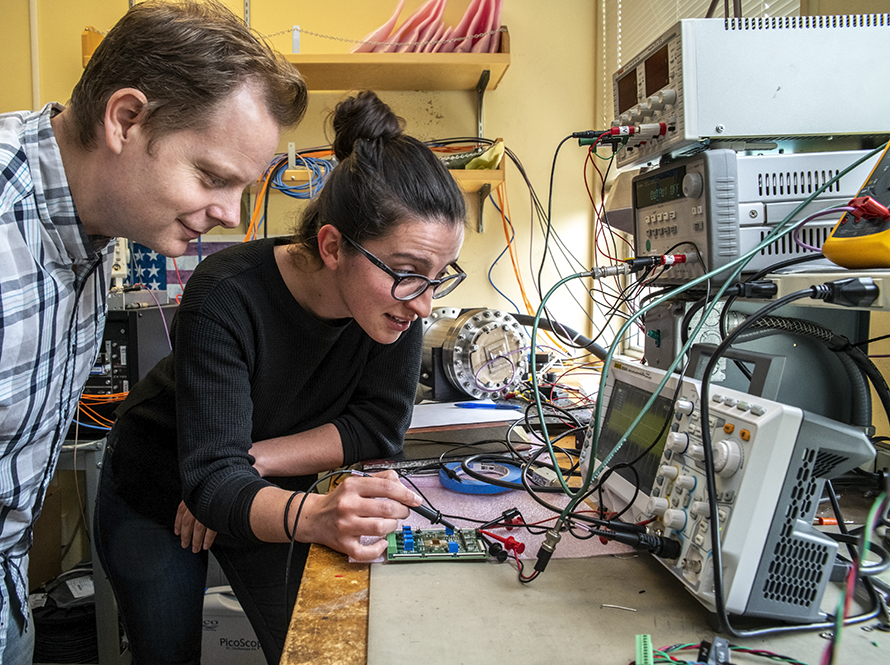

The Division collaborates with researchers to enable groundbreaking science, designing and building the detectors that enable cutting-edge physics experiments, and pushing accelerator and beamline engineering frontiers. Capabilities include accelerator engineering, detector systems and custom electronics, fabrication and manufacturing, and project execution.

From building some of the largest physics detectors in the world to fabricating parts that are on the nano- or micron-scale, the Engineering Division plays a key role in major projects and programs throughout Berkeley Lab. Engineers and technologists are embedded within scientific divisions, serving as key members of science project teams.

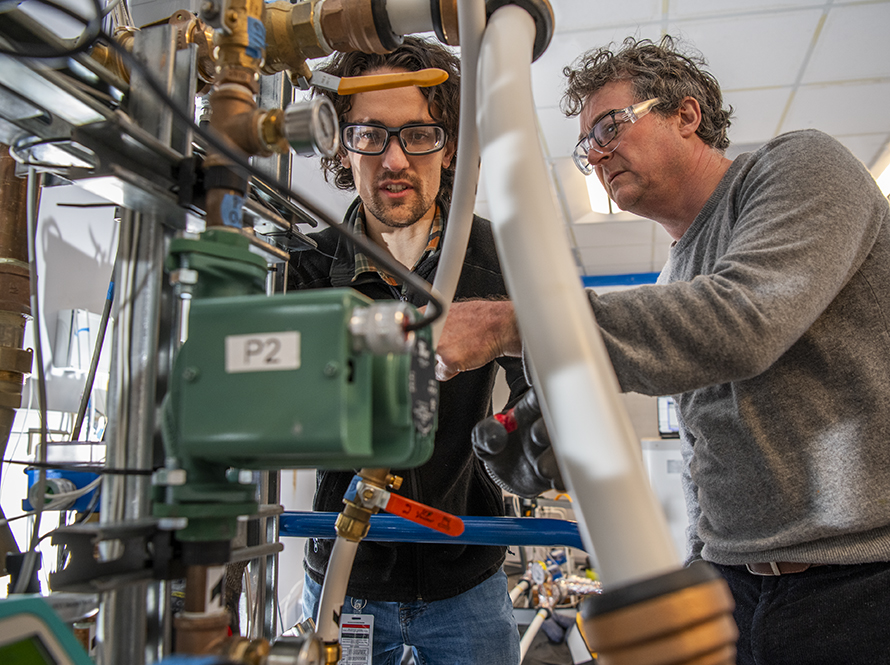

The Division is organized around five core engineering disciplines, represented by Departments within the organization. This structure enables it to deliver targeted support to key scientific areas: Mechanical Engineering; Electronics, Software, and Instrumentation; Manufacturing Engineering; Computer-Aided Design (CAD); and Project Planning and Controls. In addition, we collaborate with the ATAP division to lead a center of excellence for high performance magnet systems.

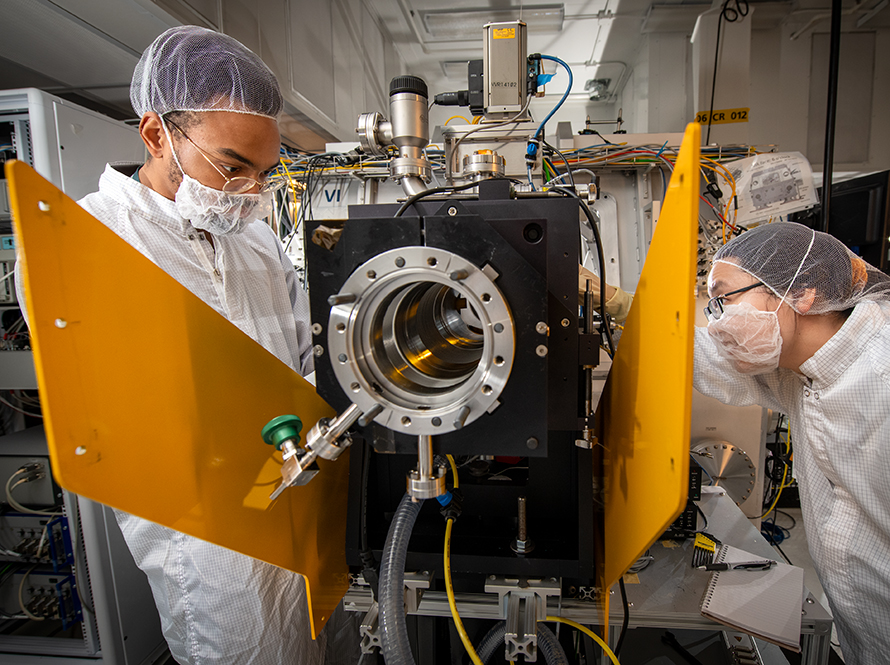

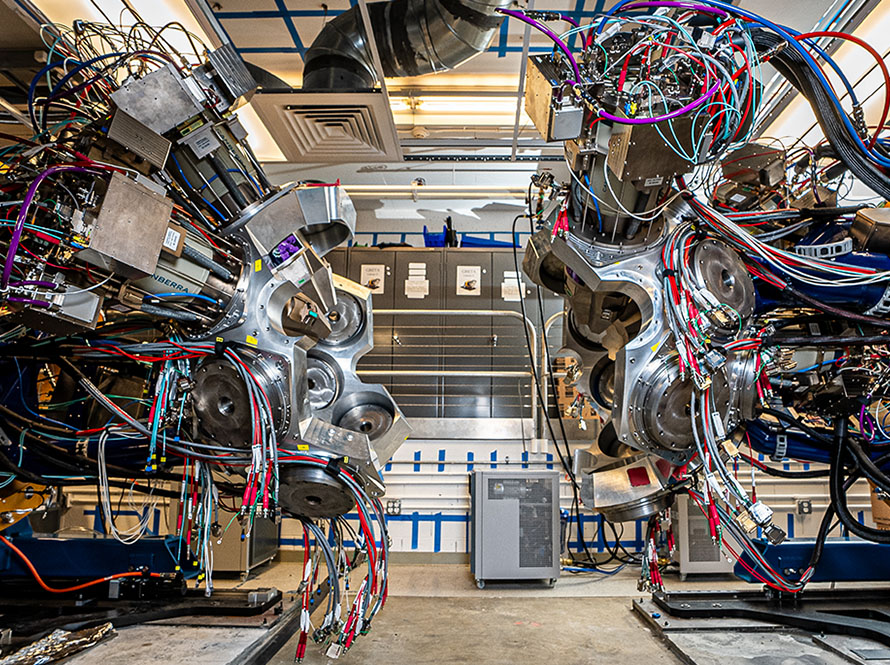

Making GRETA: How Engineering is helping bring the world’s most sensitive gamma-ray spectrometer to life

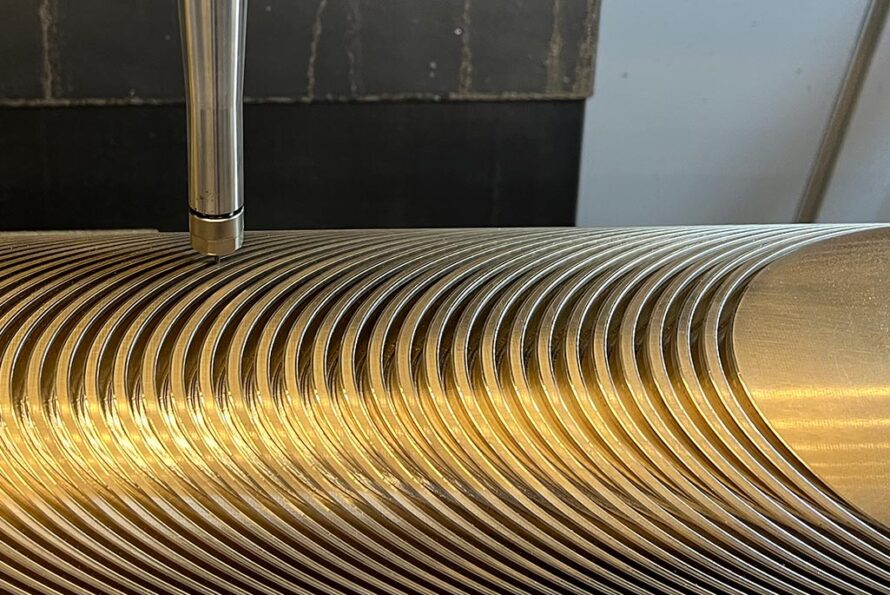

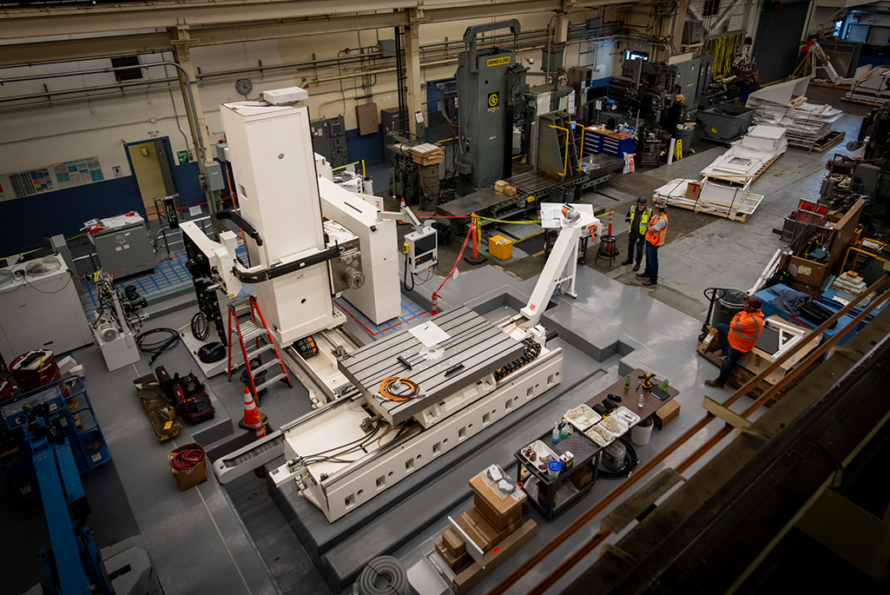

Berkeley Lab’s Engineering Division Unveils Its New Computer Numerical Control Machine

Discovery to Delivery: 3Q4 with Senajith “Seno” Rekawa

Made in Berkeley Lab: elegant arcs for superconducting magnets