CERN’s ATLAS detector, the largest detector ever constructed for a particle collider, has been undergoing a multi-year upgrade to overhaul its innermost tracking system. The upgrade, which will come online in 2029, achieved a major milestone recently when layer 3 (L3) and layer 2 (L2) of the four layers that will form the strip detector were delivered to CERN, and their integration with the tracker’s outer cylinder (OC) was successfully completed.

ATLAS’s detector upgrade coincides with the High-Luminosity Large Hadron Collider (HL-LHC) upgrade currently underway at CERN. ATLAS’s inner tracking system is the part of the tracker closest to the paths of particles produced by collisions in the collider and plays an important role in recording particle activity. The upgrade will completely replace ATLAS’s current detector with a new all-silicon inner tracker, referred to as the ITk. The ITk has been specifically engineered to accommodate an increased rate of simultaneous proton collisions (proton-on-proton pile-up), data rates, and radiation levels produced by the HL-LHC, while improving particle tracking performance. The ITk will also improve ATLAS’s ability to reconstruct particles and identify rare processes.

The multi-year process of designing and building the new ITk has been a long-term project for Berkeley Lab’s Engineering and Physics Divisions. ITk Project Engineer Eric Anderssen, who has worked on ATLAS since 1997, joined the team for the new ITk in 2015, and Mechanical Engineers Jessica Aguilar, Todd Claybaugh and Giorgio Vallone joined in 2018. The Engineering Division team has been key to the project, providing the expertise driving the detector’s planning, design, fabrication, assembly, qualification, and installation. The equipment, assembly processes, and all of the safety documents were designed and managed by the Engineering Division at Berkeley Lab.

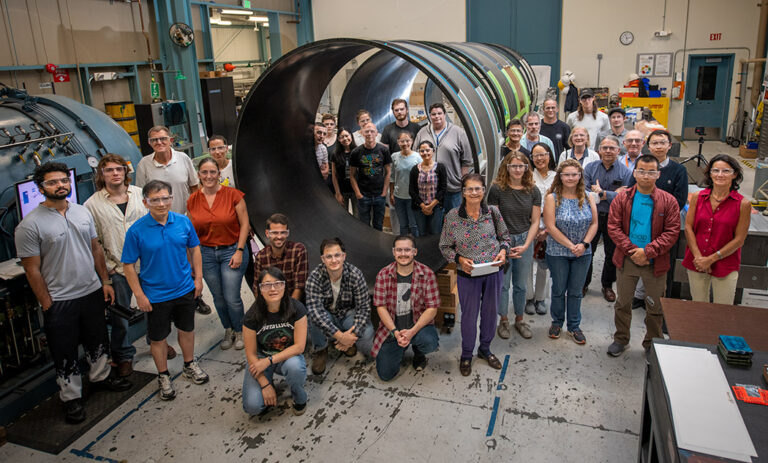

Members of the ATLAS team with the outer cylinder at Berkeley Lab. (Photo credit: Thor Swift, Berkeley Lab)

The Physics Division team includes several scientists, and more than a dozen postdocs and students who have worked on the project for more than a decade, and who are heavily engaged both on the instrumentation side and in the analysis of the data from the ATLAS detector to improve our understanding of particle physics. Their hardware contributions range from the design of the upgraded detector layout and the low-level front-end electronics to the current production of some of the complex active detector elements that will eventually be mounted on the lightweight carbon-based support structures. This current upgrade of the inner detector is a major milestone towards enabling even more powerful data collection and analysis.

“This project is both an international project but also a U.S.-wide project, and so we’re part of an enormous collaboration,” explains Anderssen. “On the project, we don’t make a huge distinction of who comes from which institution. We are all working together as a team to make this happen.”

Following L2 and L3 on their journey to CERN

When it is completed, the ITk will be made up of four carbon-fiber-composite barrels – or layers – nestled precisely within one another. The OC, which was designed at Berkeley Lab, then fabricated by a vendor, and arrived at CERN in June of 2024, will provide the frame that supports the entire structure. L3 and L2 are the first of the inner barrels to be delivered to CERN.

“This object, L3, the skin is only 600 microns thick,” Anderssen says. “That’s about a thirty-secondth of an inch. Structurally, this whole object weighs about 65 or 75 kg. It’s very light for its size, but it’s 3 meters in diameter and 2.8 meters long. So, it’s very large and very light. The real challenge is, these are very fragile objects, so designing them to be as light as possible yet still robust enough to do their job is the difficult aspect.”

Following L3 and L2 on their journey to CERN provides an appreciation for the dedication, meticulous engineering, and tremendous technical skill that go into creating each of the component parts of a detector like ATLAS.

The planning and design for the layers was accomplished at Berkeley Lab, though due to their immense size, which is substantially larger than equipment at the Lab is able to accommodate, the initial fabrication of the barrels was contracted out to a firm in San Diego, California. The Berkeley Lab team worked closely with the firm to manage the fabrication process, then, in spring 2023, the barrels arrived in Berkeley for assembly and qualification.

Once the barrels arrived at Berkeley Lab, Engineers and technicians worked on assembly of components including the copper Kapton flex heaters that are mounted on the barrels. These heaters are critical for preventing damage to the silicon detectors, which cannot withstand drastic temperature changes. They help prevent condensation on the outer surface of the detector, which operates at extremely cold temperatures of around -40°C.

Another component of the structure, called rails, were precision bonded in the Lab’s fabrication shop. The rails hold polymoderator tiles, which help protect the detector. After this portion of the assembly work was completed at Berkeley Lab, L3 and L2 successfully completed the qualification process, ensuring they are functioning properly. Then, the barrels continued on to the next stage of their journey, which brought them to Oxford University, in England, where optic brackets were mounted. Finally, L3 and L2 proceeded on to CERN.

Global mechanics integration at CERN

Integration of the OC with L3 and L2 was the next step in the process. Berkeley Lab engineers traveled to CERN to assist in completing this important project milestone.

The final precision pin is inserted into the outer cylinder at CERN. Photo credit: Eric Anderssen, Berkeley Lab

“It’s amazing how many critical decisions you can make just sitting with someone at a table, just looking at the same spreadsheet or CAD, or whatever it is,” Todd Claybaugh remarks on the several trips he’s made to CERN to support the project. “Those interactions really are critical. It’s so essential to the project.”

Polymoderator tiles with spark shields are installed at CERN. The tiles shrink and expand with temperature changes. Photo credit: Eric Anderssen, Berkeley Lab

The integration process of the outer cylinder with L3 and L2 began in June 2024. First, the barrels were carefully unpacked and inspected after shipping. The outer cylinder was lifted into a specially designed cradle, purpose-built to hold the cylinders during the integration process. Following this, the entire system – cradle and outer cylinder – was together transported to a clean room. There, more assembly work was completed, including the installation of neutron-absorbing polymoderator tiles and spark shields, which line the interior of the outer cylinder.

L3 was then prepped for integration and introduced into the clean room, and then carefully inserted into the casing of the outer cylinder. This entailed gently sliding L3 into the housing of the outer cylinder using a purpose-engineered insertion tool. Each cylinder has hundreds of mounting holes that must all line up within two tenths of a millimeter – which is about the thickness of two sheets of paper. Thanks to the engineering work and the qualification completed by Berkeley Lab, all of the mounting holes aligned, and everything fit perfectly.

“Everything went exceedingly well,” notes Anderssen. “The engineer’s first job is to make sure everything fits, but that’s remarkably challenging to do when you have a large, thin-walled, flexible structure that’s an assembly of precision objects that are hard to measure on their own.”

Layer 2 insertion took place in September 2024 and was also completed with no issues.

“When we were inserting Layer 2, I had allocated a week,” mentions Claybaugh. “This was my estimate based on how slowly things can go at CERN because of factors like working in an unfamiliar location and not having access to all the tools that I’m used to having. I thought that a week would not be enough time, but it turned out to be more than enough time! It was surprising to me how smoothly things went.”

Now that L3 and L2 integration is complete, the team is working on the next phase of the project. Currently, L1 and L0 are being built at Berkeley Lab. These two components will be integrated into the overall detector in 2027. The Lab is also contributing to building the modules and the staves for the strip detectors, as well as the pixel modules and the pixel structures for the pixel detectors. All of these structures are in the preproduction phase and will be transitioning to production later this year.

The assembly of the ITk is expected to be completed over the next three years. When it is finished, the whole detector will be installed about 100 meters underground, where it will replace the current ATLAS inner detector.

The ATLAS detector upgrade is a project ideally suited to draw on the engineering skill sets at the Lab. The Berkeley Lab composite shop has been designing and constructing silicon-based tracking detectors since the original ATLAS detector was built in the early 2000s – in fact, it was established to build the original ATLAS inner detector.

The current ATLAS detector played a critical role in the discovery of the Higgs boson in 2012. When the ITk upgrade starts yielding data, it will provide an order of magnitude more information than the current detector. This will enable further exploration of the Higgs boson, as well as valuable new insight into cutting-edge areas of physics.

“CERN is the beating heart of particle physics. It is the center of the world for that,” remarks Claybaugh. “There aren’t a lot of industries where you can say, this is the place where literally everybody wants to be. So going to CERN is a very special thing. And the people you meet there are so motivated, and so focused, and intelligent.”